| –

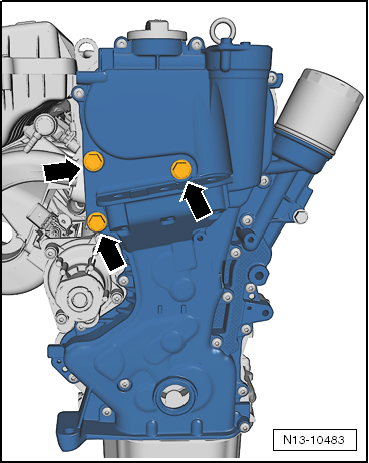

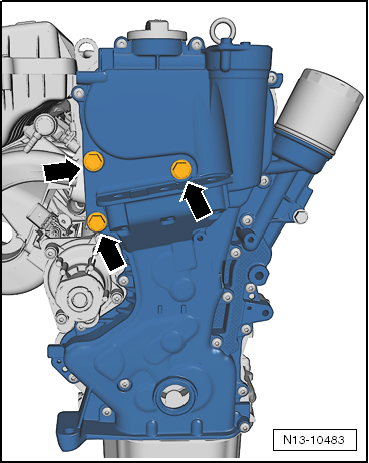

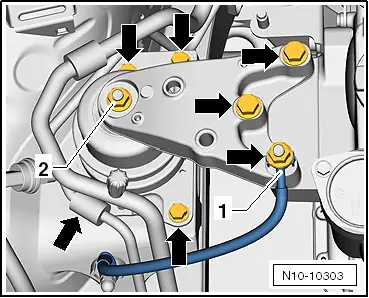

| Undo socket bolts of valve timing housing. |

| –

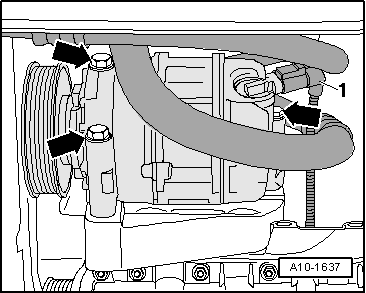

| Undo the marked socket bolts -arrows-. |

| –

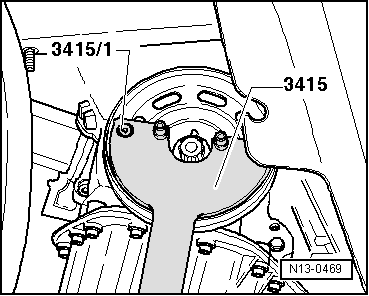

| Remove distribution chain. |

Note | Crankshaft bearing bush remains in sealing flange. |

| Installation is in the reverse sequence of removal. Note the following: |

Note | The pulley contact surfaces, securing bolt, bearing bush and crankshaft chain sprocket must be free of oil and grease. |

| –

| Clean sealing surfaces carefully. They must be free of oil and grease. |

Note | t

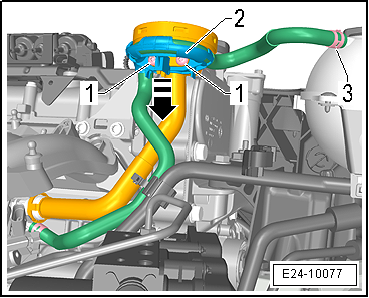

| The valve timing housing is still sealed to the engine with a seal and also sealant D 176 501 A1. |

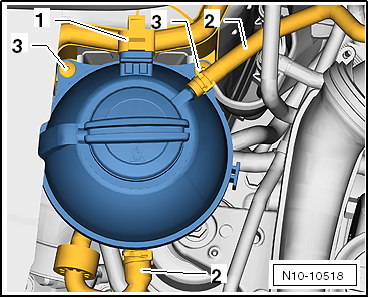

| t

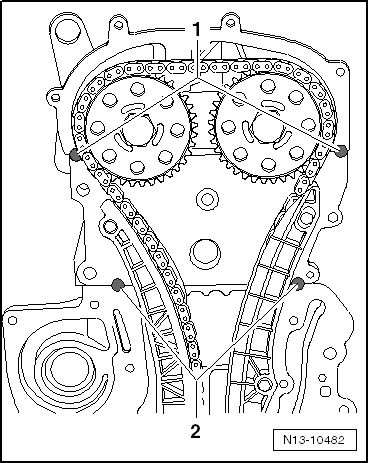

| The sealant D 176 501 A1 is used to prevent leaks between the valve timing housing and the joints -1- and -2-. |

| t

| The sealant point must have a diameter of 10 mm and a thickness of approx. 1 mm. |

| t

| Do not apply sealant until directly before the valve timing housing is fitted. |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note Note

Note Note

Note