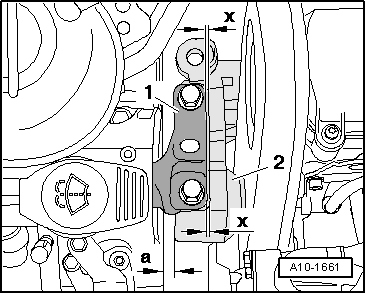

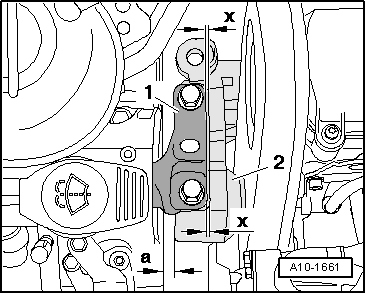

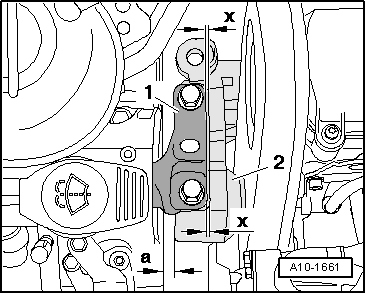

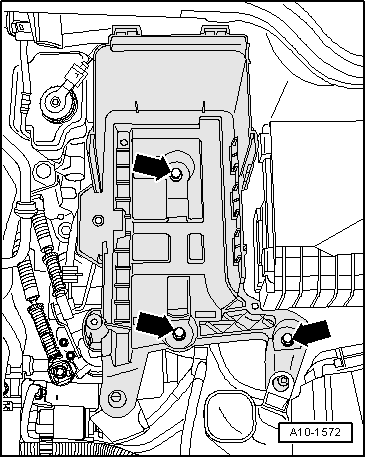

| The following dimensions must be reached: |

| t

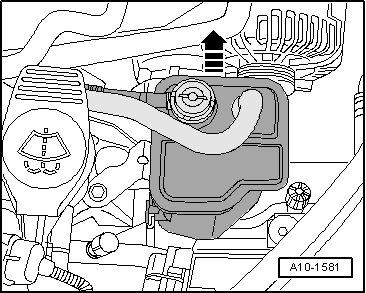

| Between the engine support and the right longitudinal member there must be a distance of -a- = 16 mm. |

| t

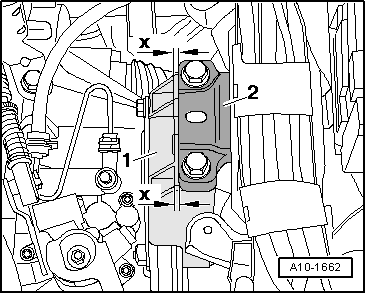

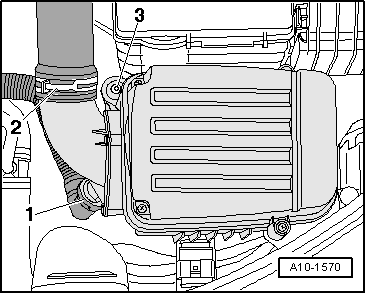

| The moulded edge at the engine support foot -2- must be parallel to the support arm -1- (dimension-x- = dimension-x-). |

Note | t

| The dimension -a- = 16 mm. can be checked, for example, with an appropriate cylindrical object. |

| t

| If the gap is too narrow or too wide, settings must be carried out → Anchor. |

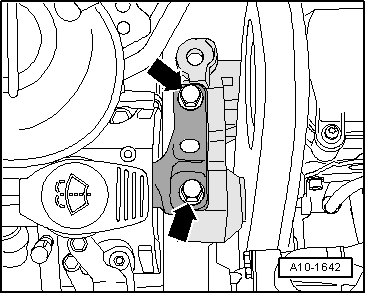

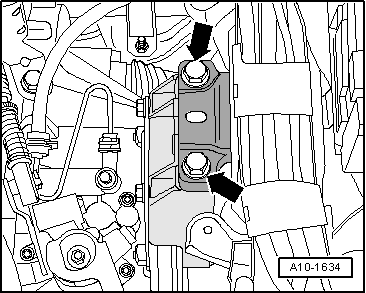

| Assembly mounting: adjusting |

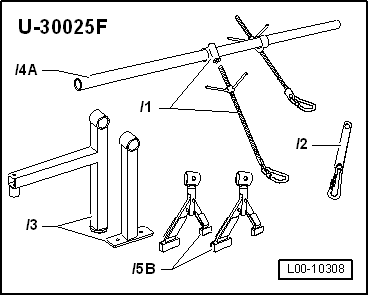

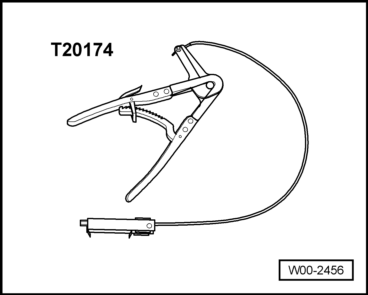

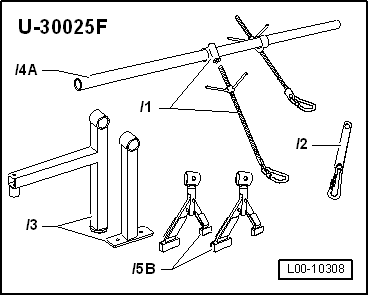

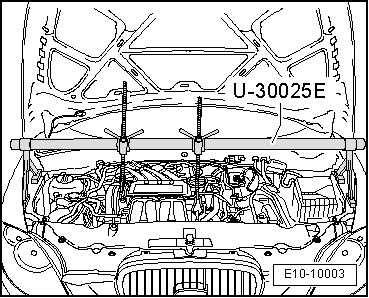

| Special tools and workshop equipment required |

|

|

|

Note

Note

Note

Note