| Installation is carried out in the reverse order. When installing, note the following: |

Caution | When doing any repair work, especially in the engine compartment, pay attention to the following due to the cramped conditions: |

| t

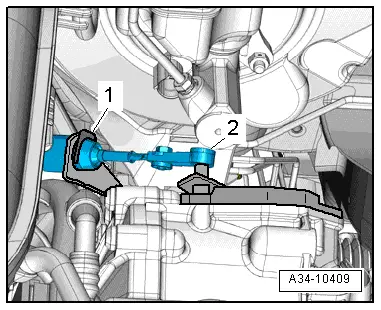

| All the various lines (e.g. fuel, hydraulic system, active carbon filter system, coolant, refrigerant, brake fluid and vacuum pipes and hoses) and electrical wiring must be installed in their original positions. |

| t

| To prevent damaging the hoses, ensure that all mobile or hot components are easily accessible. |

|

| Vehicles with Manual gearbox |

| –

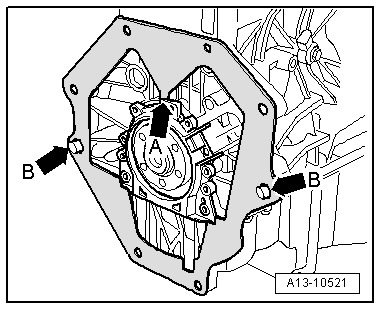

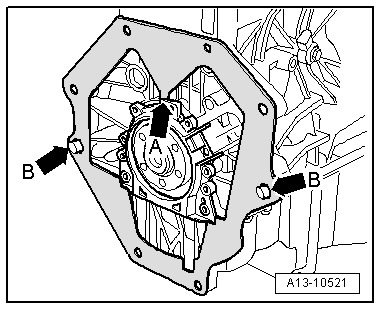

| Check wear to the clutch release bearing and replace if necessary. |

| –

| Lubricate clutch release bearing, guide sleeve for release bearing and splines of input shaft with a small quantity of G 000 100. |

| –

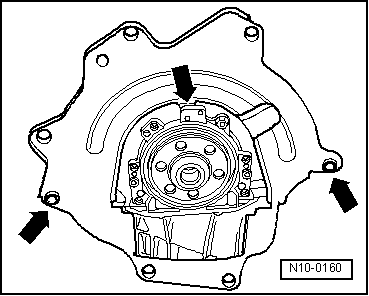

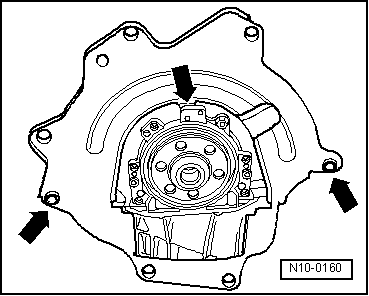

| Check whether the dowel sleeves for centring engine/gearbox are in the cylinder block, install if necessary. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note