| –

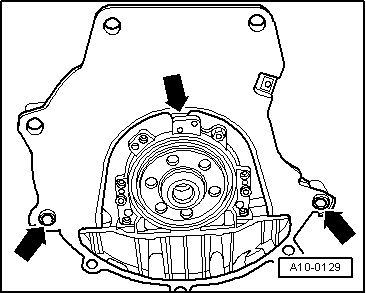

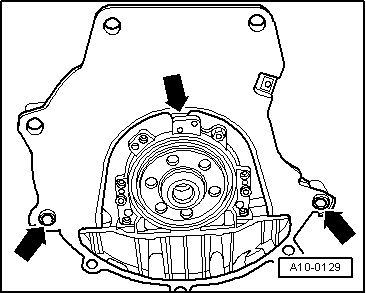

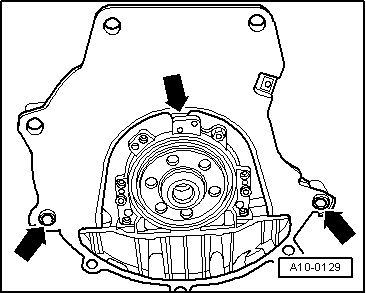

| Fit intermediate plate onto sealing flange and slide onto dowel sleeves -arrows -. |

| –

| Renewing needle bearing in crankshaft → Chapter. |

| –

| When installing engine and gearbox assembly, ensure sufficient clearance to subframe and radiator. |

| –

| Adjust the mechanical group mountings → Chapter |

| –

| Read out and erase all fault memory that may have been registered as a result of the fitting. |

| –

| Take vehicle for a test drive. |

| –

| A check of the vehicle system test should be carried out immediately afterwards. Possible error messages must be deleted. |

Note |

|

|

Note

Note

Note

Note