| –

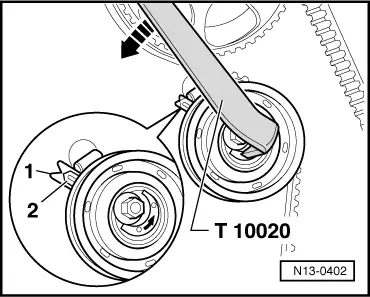

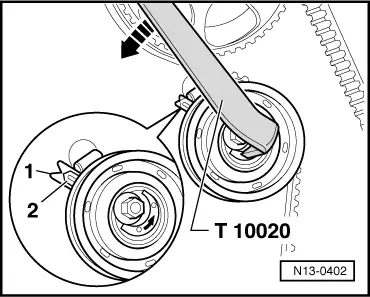

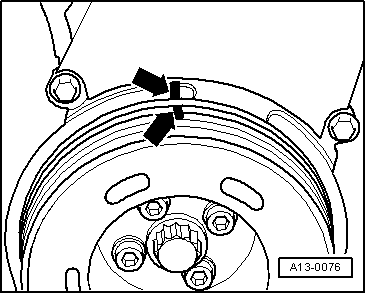

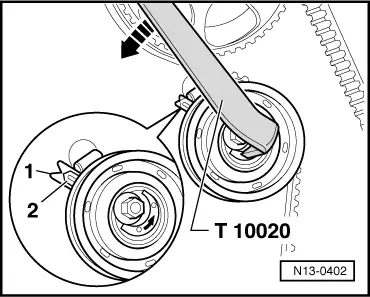

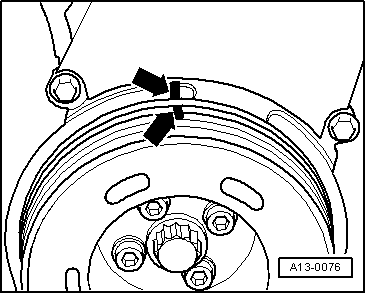

| Tense the notched belt. For this purpose, turn the pin wrench -T10020- on the eccentric adjuster to the left (direction of the arrow) until the indicator -2- is positioned above the notch -1- (over tensioned toothed belt). |

Note | Repeat this operation (tension the timing belt) five times so the timing belt settles. |

| –

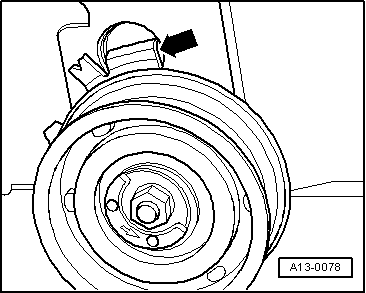

| Now tense the toothed belt until the notch -1- and the pointer -2- align. |

| –

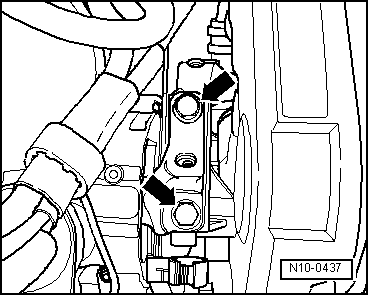

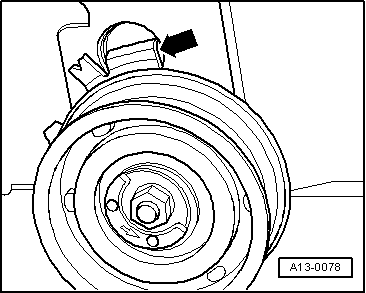

| Tighten the fastening nut to 20 Nm. |

| –

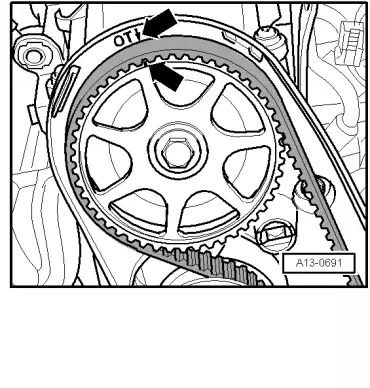

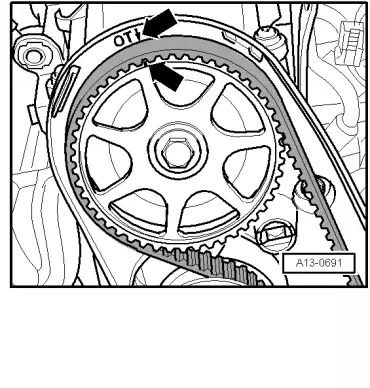

| Rotate the crankshaft twice in the normal direction of rotation so that it is positioned back on the TDC cylinder 1. It is important that the final 45° (1/8 turns) are performed without interruption. |

| –

| Check again if timing belt is tense. Specification: Needle and notch align. |

| –

| Check valve timings again. |

| If the marks do not coincide: |

| –

| Readjust the valve timings. |

| –

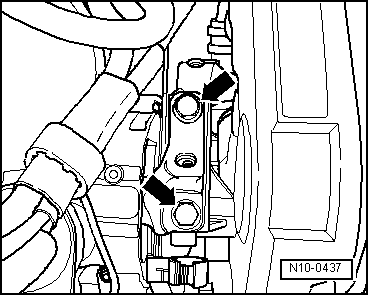

| Fit the engine bracket on the cylinder block from above and tighten both top fastening bolts to 45 Nm. |

| –

| Lower the engine up to assembly position. |

| –

| Screw in the bottom bolt and tighten the bolt to 45 Nm. |

| –

| Fit the engine assembly support completely. Tightening torques → Chapter |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note