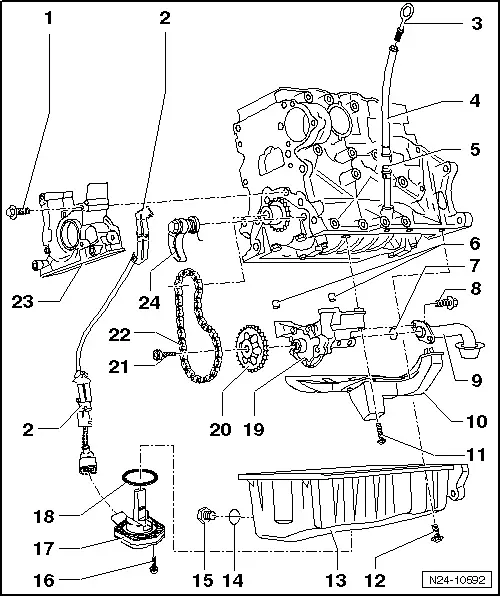

Leon Mk1

| Part I oil pump |

| 1 - | 15 Nm |

| 2 - | Support |

| q | For oil level and oil temperature sender -G266- cable harness |

| 3 - | Dip stick |

| q | Oil level must not be above max. mark on dipstick! |

| q | Marks → Fig. |

| 4 - | Filling funnel |

| 5 - | Guide pipe |

| 6 - | Dowel sleeves |

| 7 - | O ring |

| q | replace |

| 8 - | 15 Nm |

| 9 - | Oil suction pipe |

| q | Clean strainer if dirty |

| 10 - | Baffle plate |

| 11 - | 15 Nm |

| 12 - | 15 Nm |

| 13 - | Oil pan |

| q | Clean sealing surface before installing |

| q | Install with silicone sealant -D 176 404 A2- → Chapter. |

| 14 - | Oil seal |

| q | Rolled onto the oil drain plug |

| 15 - | Oil drain plug, 30 Nm |

| q | Screw with seal that cannot be lost |

| 16 - | 10 Nm |

| 17 - | Oil level/oil temperature sender -G266- |

| q | check → Vehicle diagnostic, testing and information system VAS 5051„function and component selection mode“ |

| 18 - | Oil seal |

| q | replace |

| 19 - | Oil pump: |

| q | With pressure relief valve 12 bar |

| q | Before installing, check that both dowel sleeves for centring oil pump on cylinder block are fitted. |

| q | Replace if there is scoring on the friction surfaces or the gear teeth. |

| q | removing and fitting → Chapter |

| 20 - | Pinions |

| 21 - | 20 Nm + 90° |

| q | replace |

| 22 - | Chain for oil pump |

| 23 - | Sealing flange |

| q | removing and fitting → Chapter |

| q | Install with silicone sealant -D 176 404 A2-. |

| q | Replace crankshaft oil seal - pulley side. → Chapter |

| 24 - | Chain tension device with tensor rail, 15 Nm |

| q | Pre-tension spring and engage before installing |