| Hydraulic pushers: verification |

| Special tools and workshop equipment required |

| t

| Wooden or plastic wedge |

Note! | t

| The hydraulic cam followers should always be replaced in their entirety (they cannot be adjusted or repaired individually). |

| t

| Unusual noises from the valves during starting are normal. |

| –

| Start the engine and run until the radiator ventilator starts once. |

| –

| Increase speed to approx. 2500 rpm for 2 minutes. |

| If the hydraulic cam followers continue to make a noise check to see which one/s is/are faulty as follows: |

| –

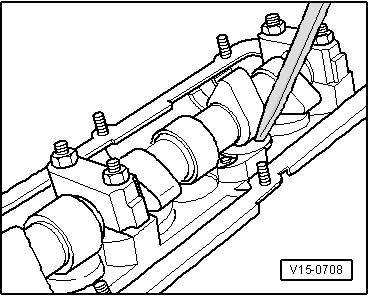

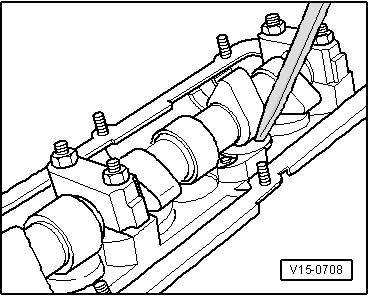

| Turn the crankshaft clockwise until the cams of the followers to be checked are facing upwards. |

| –

| Check the clearance between cams and followers. |

| –

| If it is greater than 0.2 mm, replace the follower. If it is less than 0.1 mm or if there is no clearance , proceed as follows with the check: |

|

|

|

Note!

Note! Note!

Note!

Note!

Note! Note!

Note!