Leon Mk1

| Cylinder head: disassembly and assembly |

Note!

Note!| t | Replace cylinder head bolts as a rule. |

| t | On assembling, replace self-locking nuts, bolts subject to goniometric tightening, as well as o-rings and gaskets. |

| t | The sleeves for flexible tubing should be free of oil and grease before fitting. |

| t | When installing an exchange cylinder head with camshaft fitted, all the contact surfaces between the plungers and the cams must be oiled before installing the cylinder head cover. |

| t | The plastic packing pieces for protecting open valves must not be removed until immediately before fitting the cylinder head. |

| t | After the cylinder head or cylinder head gasket is replaced, all the coolant must also be replaced. |

| t | Cylinder heads which have cracks between the valve seats or between valve seat inserts and the spark plug thread can be used further without reducing service life, provided the cracks do not exceed a maximum of 0.3 mm in width, or when no more than the first four spark plug threads are cracked. |

| 1 - | Cover |

| 2 - | Gasket |

| q | Replace in case of deterioration or lack of air tight seal |

| 3 - | 10 Nm |

| q | Tighten in cross order |

| 4 - | To flexible suction tube |

| 5 - | O- ring |

| q | Replacement |

| 6 - | Plug |

| q | 15 Nm |

| q | Replacement |

| 7 - | Cylinder head bolt |

| q | Replacement |

| q | Follow the fitting instructions and the tightening/loosening orders → Anchor |

| 8 - | Connection nozzle |

| 9 - | 10 Nm |

| 10 - | O- ring |

| q | Replacement |

| 11 - | 20 Nm |

| 12 - | Support |

| 13 - | Cylinder head gasket |

| q | Replacement |

| q | For replacing, removing and fitting the cylinder head → Chapter |

| q | If replaced, change all the coolant |

| 14 - | 15 Nm |

| 15 - | 20 Nm |

| 16 - | Rear toothed belt protection |

| 17 - | Notched belt |

| q | Before removing this, mark the rotation direction |

| q | Check for wear |

| q | Do not bend |

| q | Removing and fitting, tightening → Chapter |

| 18 - | Cylinder head |

| q | Removing and fitting → Chapter |

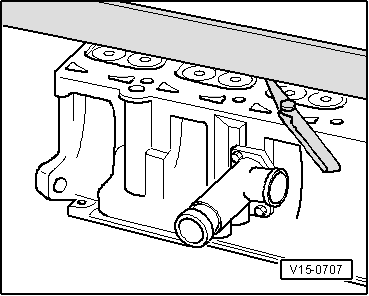

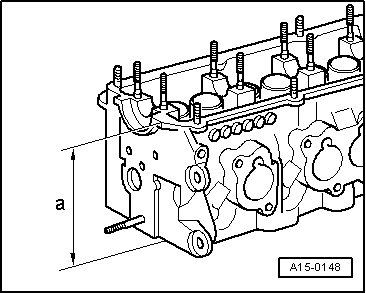

| q | Check for deformation → Fig. |

| q | Measuring the reworking the cylinder head → Fig. |

| q | If replaced, change all the coolant |

| 19 - | Oil deflector |

| 20 - | Cylinder head cover seal |

| q | Renew if damaged or leaking |

| q | Apply -D 454 300 A2- to the contact areas between the bearing caps and the cylinder head |

| 21 - | Cylinder head cover |

| q | Removing and fitting → Chapter |

|

|

|

|