| –

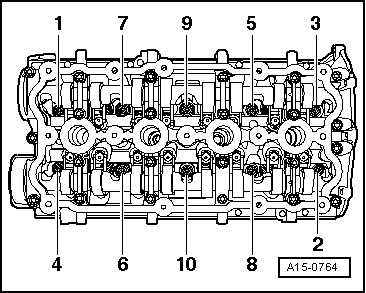

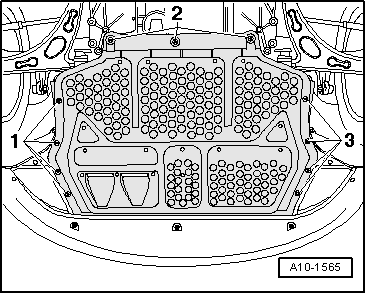

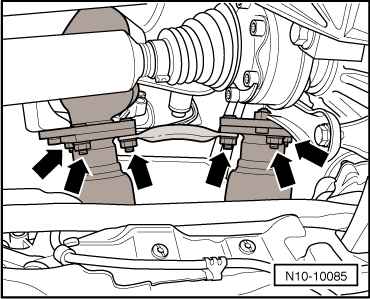

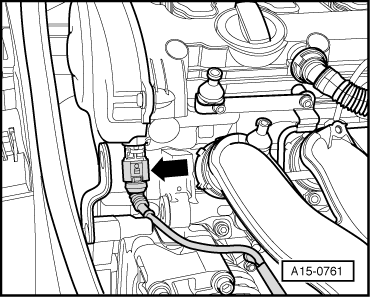

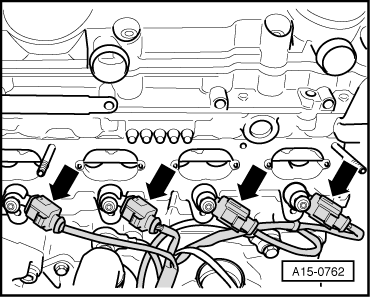

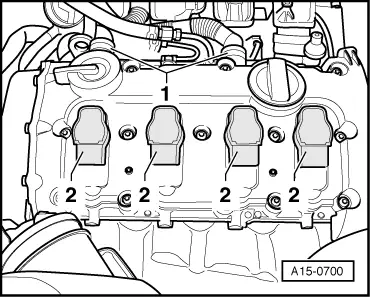

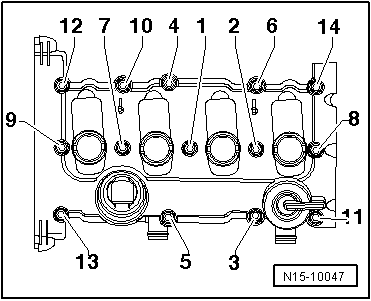

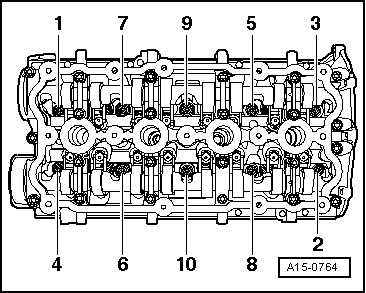

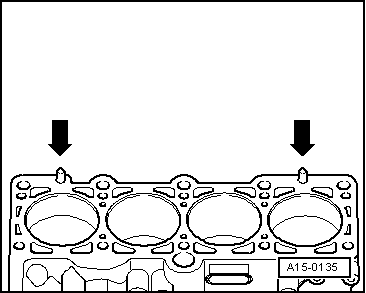

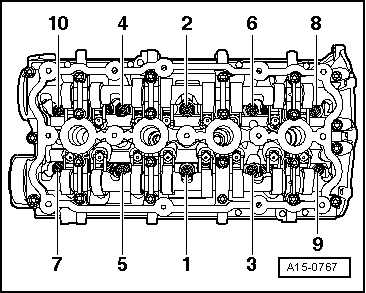

| Separate the cylinder head fastening bolts, following the order of loosening shown in the figure. |

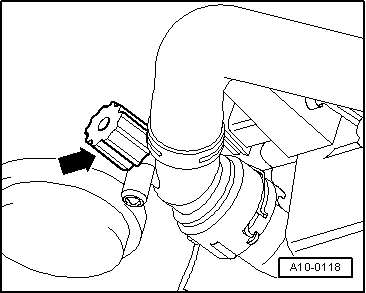

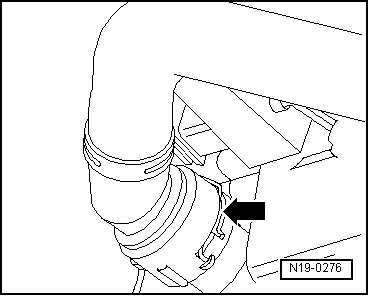

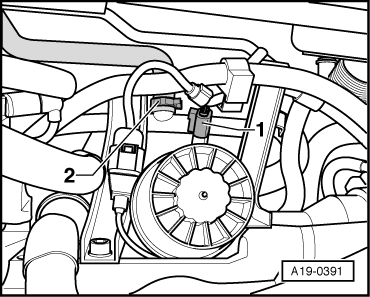

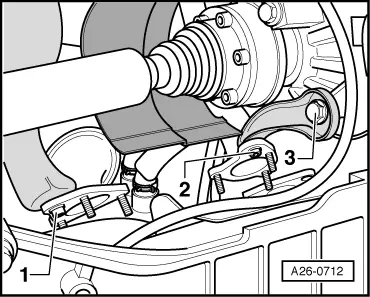

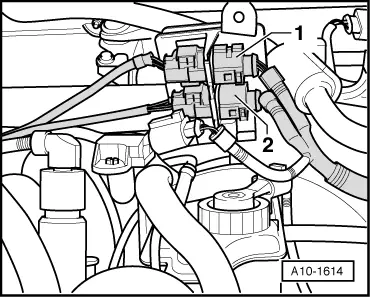

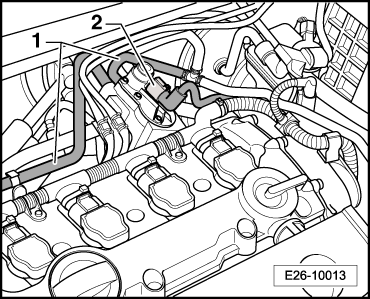

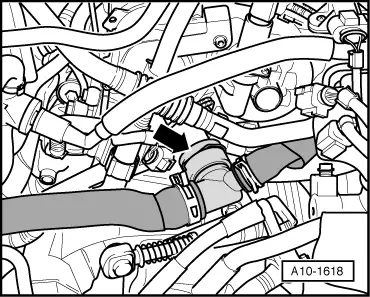

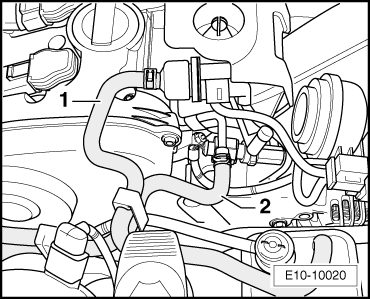

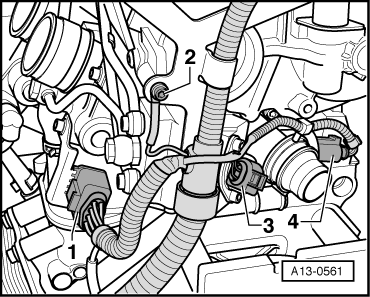

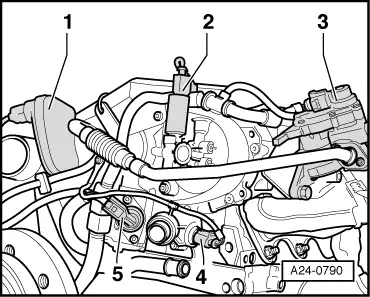

Note | Ensure that all hose attachments and tubes between the engine, gearbox and the body have been loosened. |

| –

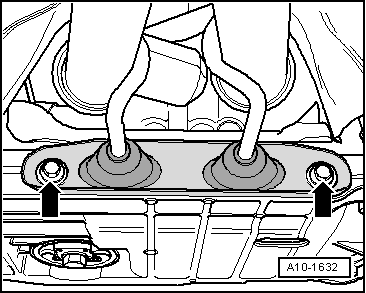

| Dismount cylinder head. |

Note | t

| Renew cylinder head bolts. |

| t

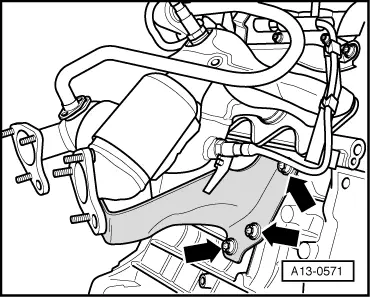

| On assembling, replace self-locking nuts, bolts subject to goniometric tightening, as well as o-rings and gaskets. |

| t

| When repairing, carefully remove any remains of gasket material from the cylinder head and cylinder block. Ensure that no long scores or scratches are made on the surfaces. |

| t

| Carefully remove any remaining emery and abrasive material. |

| t

| Remove new cylinder head gasket from packaging, just before installation. |

| t

| Handle gasket extremely carefully. Damage to the silicone coating or the indented area will lead to leaks. |

| t

| No oil or coolant must be allowed to remain in the blind holes for the cylinder head bolts in the cylinder block. |

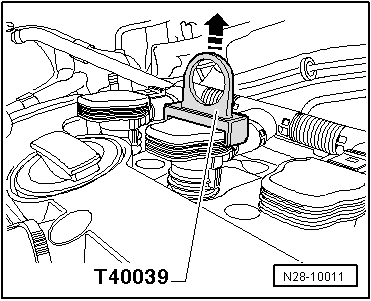

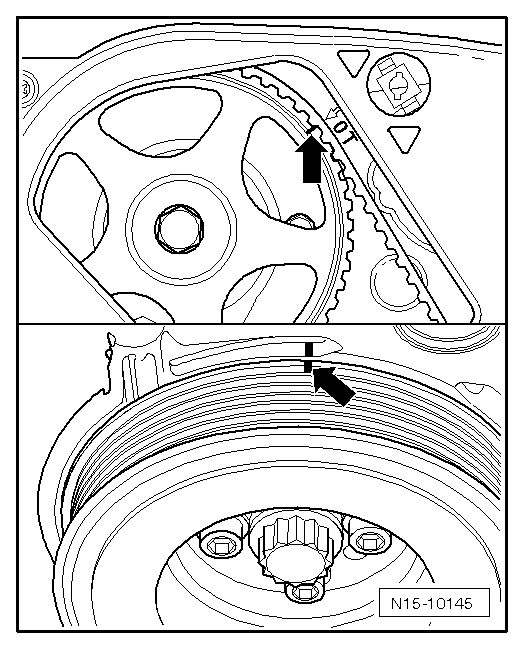

WARNING | The rotation of the engine must only take place on the crankshaft in the rotation direction of the engine (clockwise). |

|

Note | The engine should revolve around the central bolt of the crankshaft. |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note Note

Note

Note

Note Note

Note Note

Note

WARNING

WARNING