| –

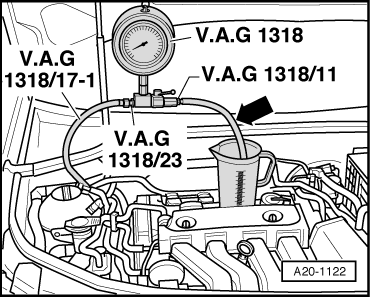

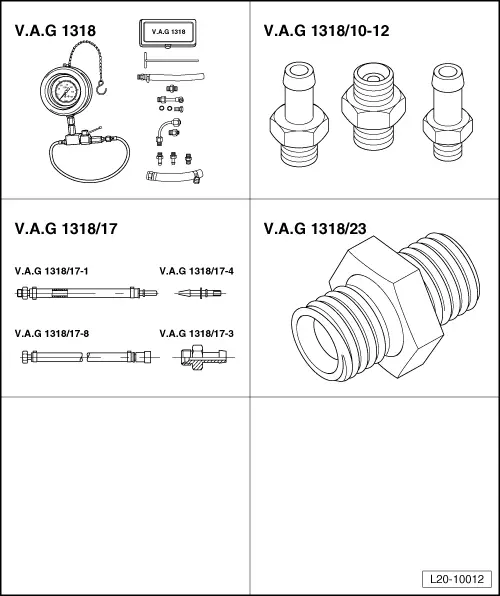

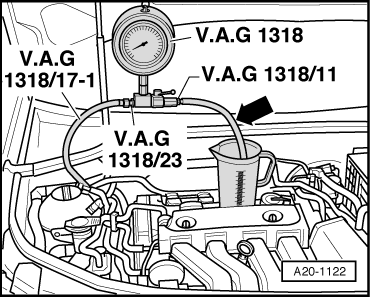

| Screw the adapter -VAG 1318/23- and the adapter -V.A.G 1318/17-1- on to the pressure tester -VAG 1318-. |

| –

| Fit the adapter -V.A.G 1318/17-1- to the disconnected fuel supply line. |

| –

| Screw the adapter -V.A.G 1318/11- on to the pressure tester -VAG 1318-. Connect the auxiliary hose -arrow- and insert the other end in a measurement container. |

| –

| Close cut-off tap of pressure tester -V.A.G 1318- (lever at right angles to direction of flow -B-). |

| –

| Operate the remote control for short periods until an overpressure of approx. 4 bar has been reached. 4.8 bar. |

WARNING | Danger of spray when opening the shut-off tap, hold container over the pressure gauge free connection. |

|

| –

| If pressure builds up too high, lower excess pressure by carefully opening the shut-off tap. |

| –

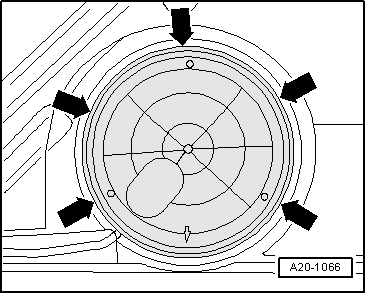

| Observe pressure drop on tester. After 10 minutes the pressure must not drop below 4 bar. |

| If the pressure drops further: |

| –

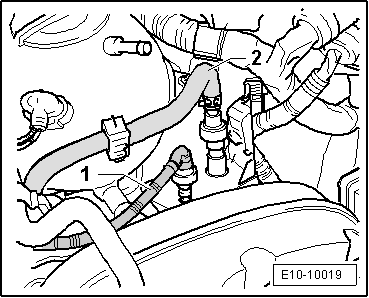

| Check the connections, O-rings and injectors for leaks. |

| –

| Test pressure gauge for leaks. |

| If no fault in lines is detected: |

| –

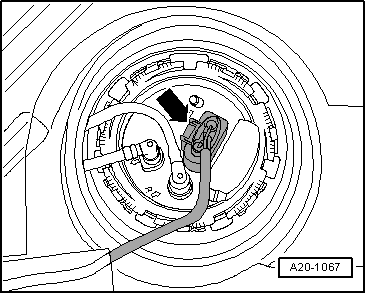

| Fuel pump retention valve is faulty, replace the fuel supply unit → Chapter . |

| Continue the installation in the reverse order of removal sequence, observing the following: |

|

|

|

Note

Note

WARNING

WARNING