Leon Mk1

|

|

|

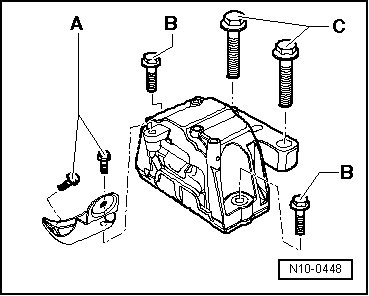

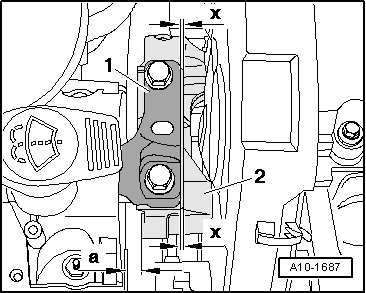

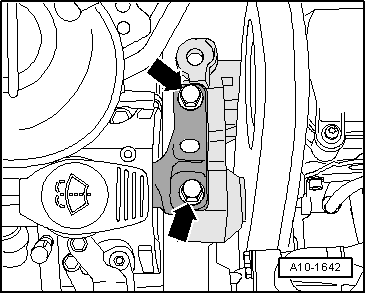

| -A-1) | 20 Nm + 90° (1/4 turn) |

| -B-1) | 40 Nm + 90° (1/4 turn) |

| -C-1) | 60 Nm + 90° (1/4 turn) |

| 1) Renew bolts | |

|

|

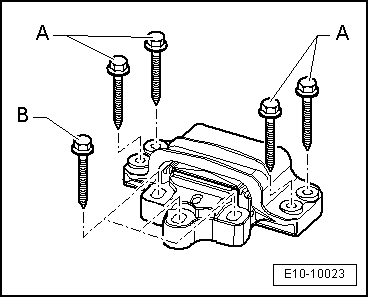

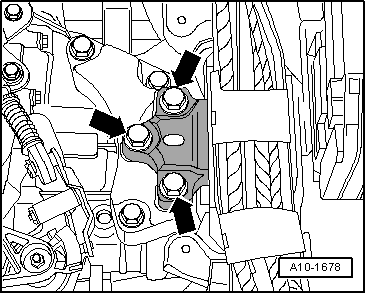

| -A-1) | 40 Nm + 90° (1/4 turn) |

| -B-1) | 60 Nm + 90° (1/4 turn) |

| 1) Renew bolts | |

|

|

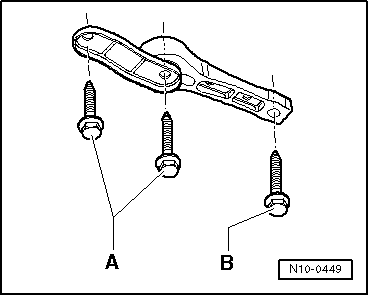

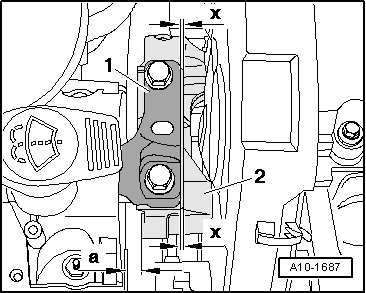

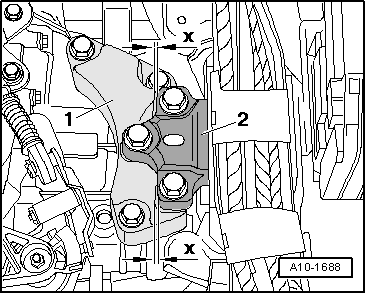

| -A-1) | 40 Nm + 90° (1/4 turn) |

| -B-1) | 100 Nm + 90° (1/4 turn) |

| 1) Renew bolts | |

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|