| l

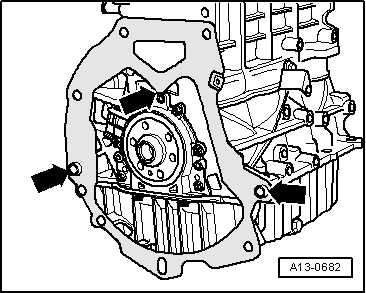

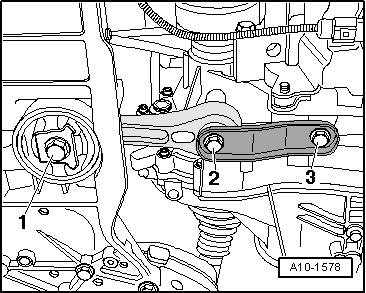

| Engine fitted on the counterhold -T20205-. |

| Installation is carried out in the reverse order of removing, when doing this note the following. |

Note | t

| When fitting, replace the self-locking nuts and bolts. |

| t

| Renew bolts which have a specified tightening angle, as well as seals and gaskets. |

| t

| Secure all hose connections with the correct hose clips (same as original equipment) → Parts catalogue. |

| t

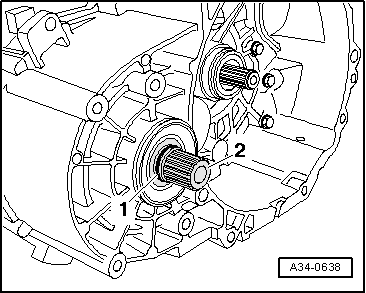

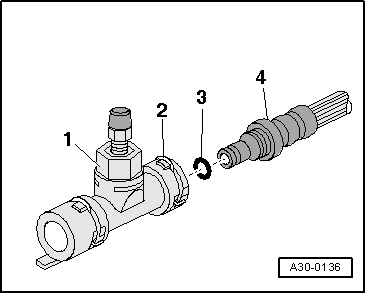

| Clean input shaft splines and, for used clutch plates, hub splines; remove corrosion and apply a thin coat of grease -G 000 100- to the splines. Then move the clutch plate on the input shaft from side to side, until the hub moves smoothly on the shaft. Excess grease must be removed. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

WARNING

WARNING