Leon Mk1

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

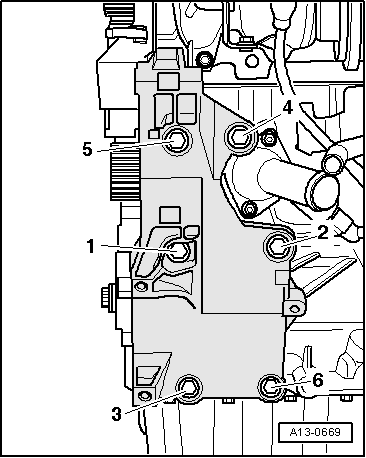

| Component | Nm | ||||

| Bracket for auxiliary units on engine block | 45 | ||||

| Return roller to ancillaries bracket | 90 + 90° 1)2) | ||||

| Engine support to bodywork | 50 | ||||

| Joint rib to engine support / bodywork | 20 + 90° 3)4) | ||||

| |||||

WARNING

WARNING