Leon Mk1

|

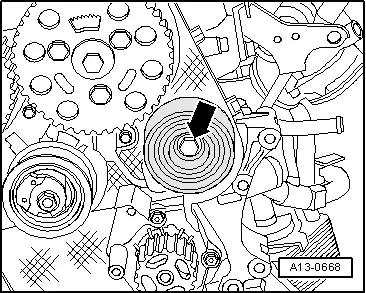

| 1 - | Cap |

| q | For vibration damper |

| 2 - | Special bolt - 10 Nm + 90° (1/4 turn) further |

| q | Replacement → Parts catalogue |

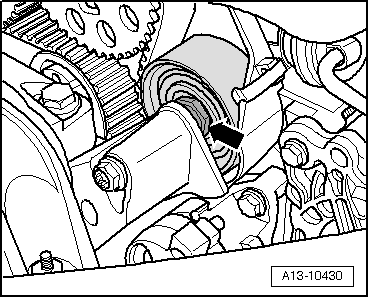

| 3 - | Vibration damper |

| q | For ribbed belt pulley |

| q | Can only be installed in one position. |

| q | removing and fitting → Chapter |

| 4 - | 10 Nm |

| q | Fit with locking fluid; locking fluid → Parts catalogue |

| 5 - | Screw for the engine support foot |

| q | Replace. |

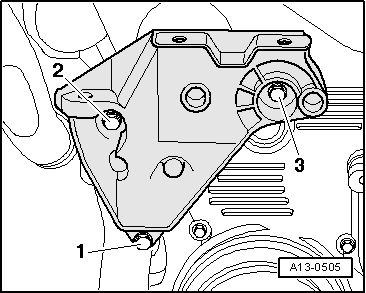

| q | Tightening torque and succession order to tighten for the small engine foot support → Fig. |

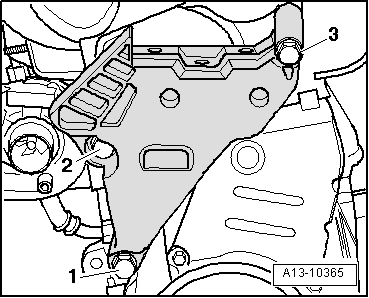

| q | Tightening torque and succession order to tighten for the large engine foot support → Fig. |

| 6 - | Engine support |

| Different procedures: |

| q | Small engine support foot → Fig. |

| q | Large engine support foot → Fig. |

| 7 - | Upper protection element for the notched belt |

| q | When fitting, carefully hook on to the centre protection for the notched belt |

| 8 - | Notched belt guard - centre part |

| q | For removal, remove the notched belt upper protection and unscrew the Poly-V belt tensioning device |

| 9 - | Notched belt guard - lower part |

| 10 - | 10 Nm |

| q | Fit with locking fluid; locking fluid → Parts catalogue |

|

|

| 1. phase |

| ||

| 2. phase |

| ||

| 3. phase |

|

|

|

| 1. phase |

| ||

| 2. phase |

| ||

| 3. phase |

|

Note

Note

|

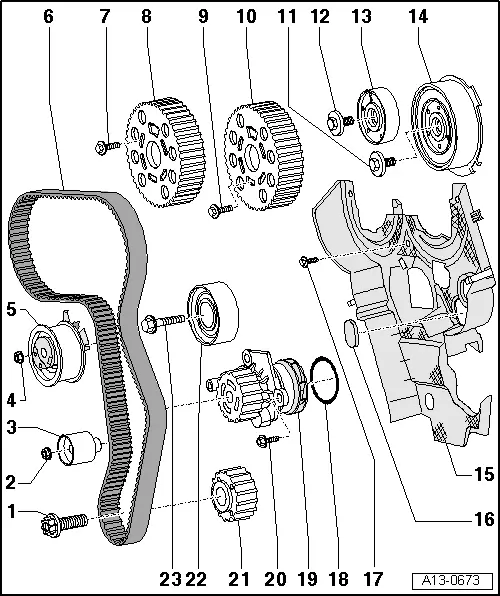

| 1 - | 120 Nm + 90° (1/4 turn) further |

| q | Replace. |

| q | Do not use oil |

| q | Use locking spanner -T20018B- to loosen and tighten → Chapter |

| 2 - | 20 Nm |

| 3 - | Idler wheel |

| 4 - | 20 Nm +45° (1/8 turn) |

| q | Use the correct tightening torque to avoid damages to the engine. |

| 5 - | Tensioning roller |

| 6 - | Notched belt |

| q | Mark direction of rotation with chalk or felt pen before removing |

| q | Check for wear |

| q | Removing vehicles with small engine support → Chapter; vehicles with large engine support → Chapter |

| q | Fitting (adjusting the valve timing): vehicles with small engine support → Anchor; vehicles with large engine support → Anchor |

| 7 - | 25 Nm |

| 8 - | Camshaft wheels |

| q | For exhaust camshaft |

| q | Mark the installation position |

| 9 - | 25 Nm |

| 10 - | Camshaft wheels |

| q | for exhaust camshaft |

| 11 - | 100 Nm |

| q | Use retention tool -T10051- to loosen and tighten, see camshaft: removing and installing → Chapter |

| 12 - | 100 Nm |

| q | Use retention tool -T10051- to loosen and tighten, see camshaft: removing and installing → Chapter |

| 13 - | Hub |

| q | For exhaust camshaft |

| q | To remove, use puller -T10052A-. |

| q | Extract → Chapter |

| 14 - | Hub |

| q | for exhaust camshaft |

| q | With sender wheel for Hall sender -G40- |

| q | To remove, use puller -T10052A-. |

| q | Extract → Chapter |

| 15 - | Rear notched belt guard |

| 16 - | Rubber grommet |

| q | If this is damaged, replace it |

| 17 - | 10 Nm |

| q | Fit with locking fluid; locking fluid → Parts catalogue |

| 18 - | O-ring |

| q | Replace. |

| 19 - | Coolant pump |

| q | removing and fitting → Chapter |

| 20 - | 15 Nm |

| 21 - | Crankshaft notched belt wheel |

| q | There should be no oil on the contact surface between the notched belt wheel and the crankshaft |

| q | Fitting is only possible in one position |

| 22 - | Idler wheel |

| 23 - | Return roller screw |

| q | Replace. |

| q | There are different screws for vehicles with small or large engine support foot |

| q | Tightening torques: vehicles with small engine support → Fig.; vehicles with large engine support → Fig. |

|

|