Leon Mk1

|

| Special tools and workshop equipment required |

| t | Torque wrench -SAT 8010-, see equivalent → Anchor. |

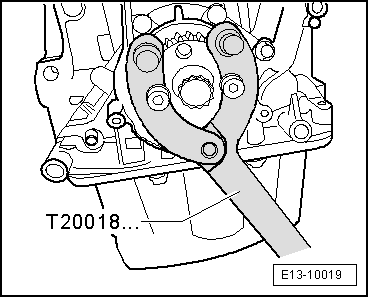

| t | Hose clamp -T20018B-, see equivalent → Anchor |

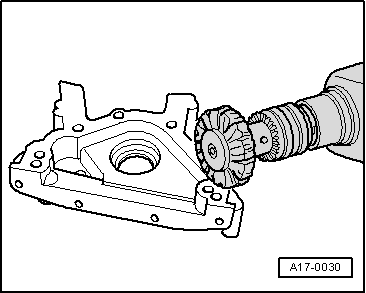

| t | Guide sleeve -T20081B-, see equivalent → Anchor |

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

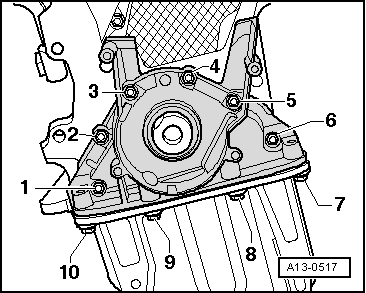

| Component | Nm | |

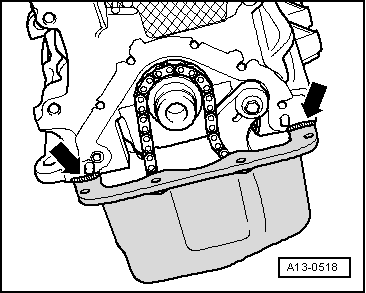

| Sealing flange to cylinder block | 15 |

WARNING

WARNING