| –

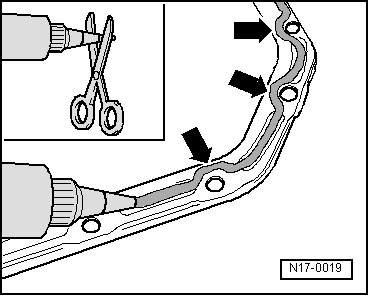

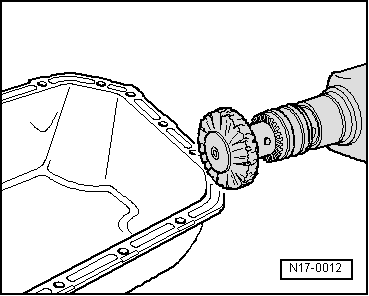

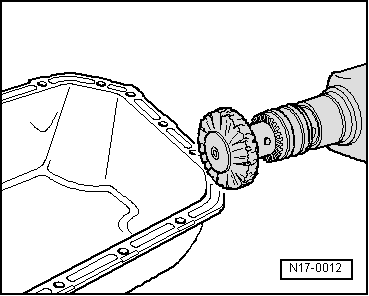

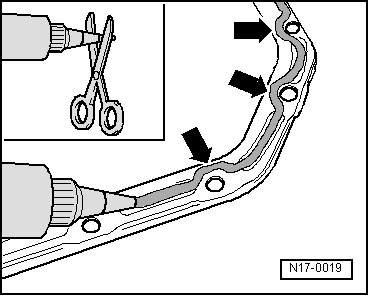

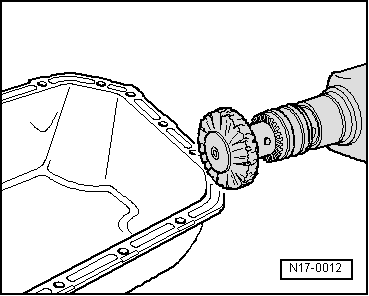

| Eliminate the remains of waterproofing agent from the sump with a rotating brush, i.e. a hand drill with the plastic brush attachment (wear safety glasses). |

| –

| Clean the hermetic surfaces. They should be free of oils and greases. |

Note! | t

| Remember the expiration date of the waterproofing agent. |

| t

| The sump must be assembled 5 minutes after applying the silicon waterproofing. |

| t

| To install the sump in a safe and easy way, introduce as guides some male screw threads in the flange points of the cylinder block M6. |

|

|

|

Note!

Note!

Note!

Note! Note!

Note!

Note!

Note!

Note!

Note! Note!

Note!