| Front section of the cardan shaft: Separating and connecting |

Note | t

| If possible, use a twin pillar lifting platform when working on the propshaft. |

| t

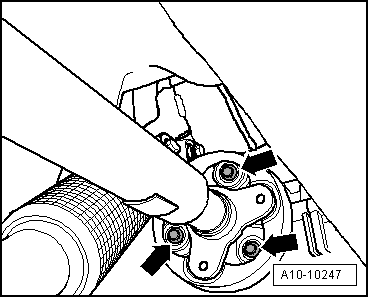

| Before removing, mark the positions of all parts in relation to each other. Reinstall in the same position to avoid excessive imbalance, resulting in bearing damage and rumbling noise. |

| t

| Do not bend propshaft, store and transport extended only. |

| t

| Always support the propshaft during removal; it must not be allowed to »hang down« from one of the joints. |

| t

| Always keep the propshaft horizontal while pulling it off or fitting it on the joint flange. |

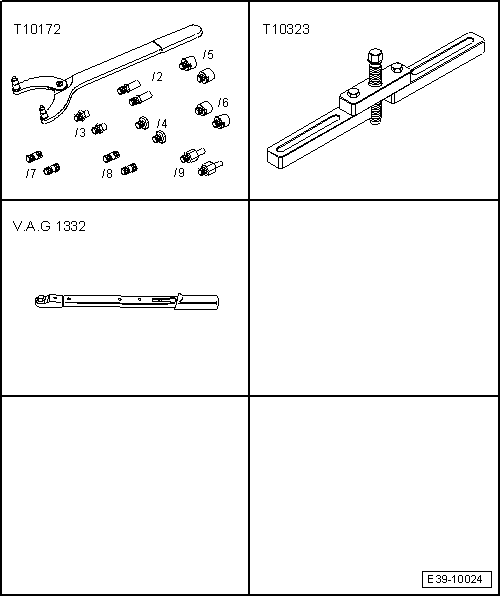

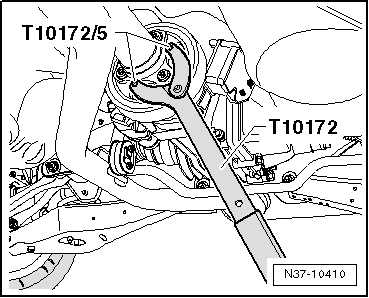

| Consult the equivalence table for tools and equipment according to applicability among Seat / VW / Audi / Skoda → Chapter. |

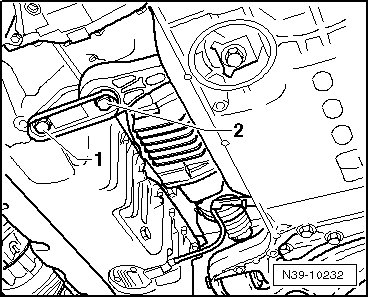

|

|

|

Note

Note

Note

Note

Note

Note

WARNING

WARNING