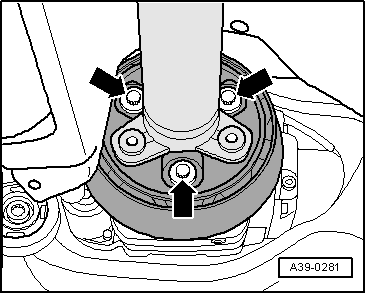

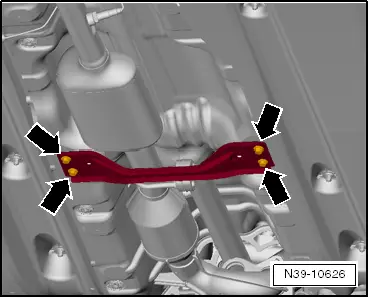

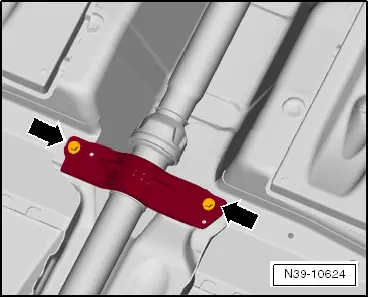

| Rear section of the cardan shaft: Separating and connecting |

Note | t

| Repairs on the propshaft should be carried out on a two pillar hoist. |

| t

| In order to achieve the quietest possible running, only the complete propshaft is balanced during manufacture. The balancing of the complete propshaft or the individual propshaft tubes cannot be carried out with workshop equipment. Therefore, in the event of damage to the front or rear propshaft tube, the entire propshaft must always be renewed. |

| t

| Do not bend propshaft, store and transport extended only. |

| t

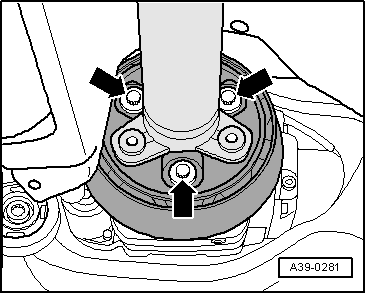

| Before removing, mark the position of each part with respect to the other parts. The parts must be reassembled in the same position. If not, the system will be excessively unbalanced. This can damage the assignments and cause noise. |

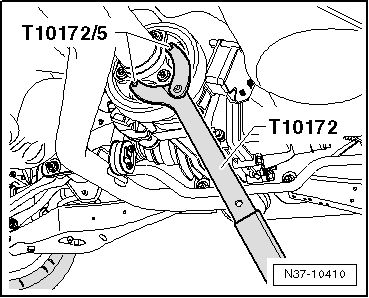

| Consult the equivalence table for tools and equipment according to applicability among Seat / VW / Audi / Skoda → Chapter. |

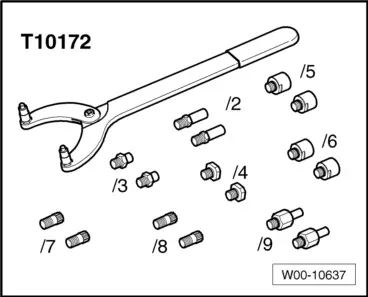

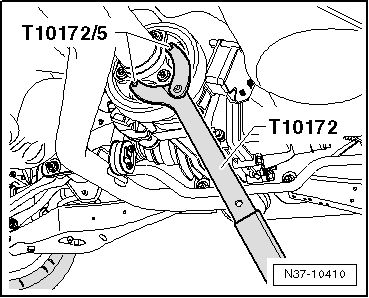

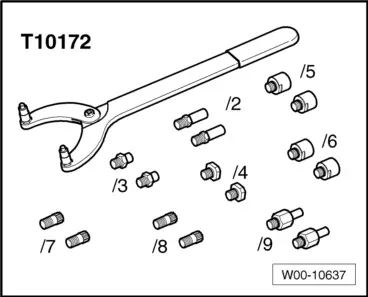

| Special tools and workshop equipment required |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note