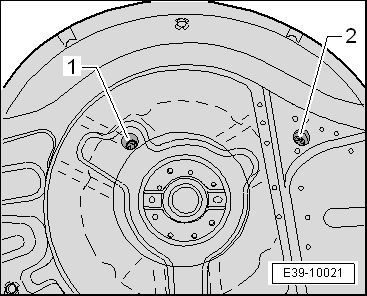

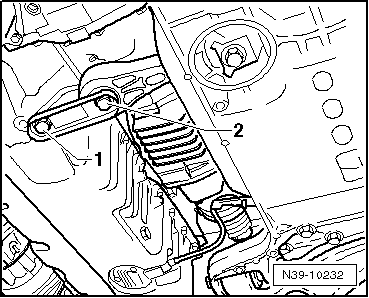

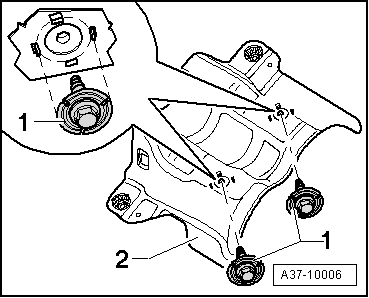

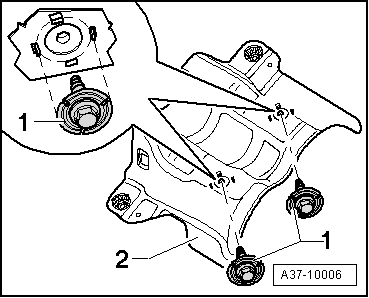

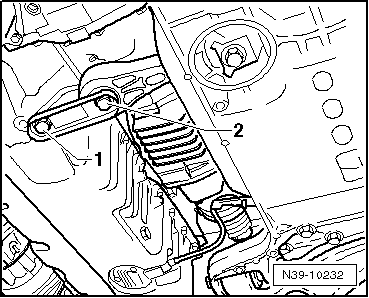

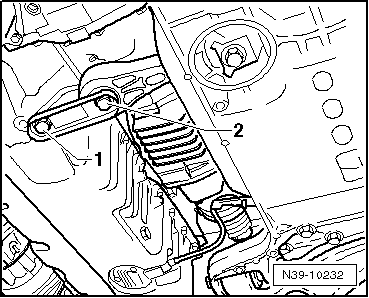

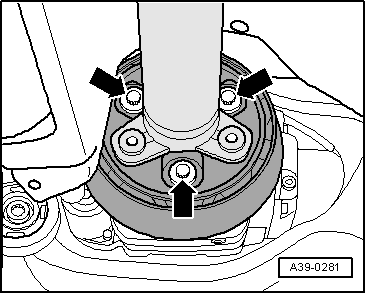

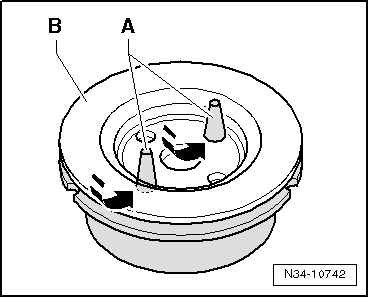

| When screwing on the heat protection plate -2- to the centre bearing, you have to check that the bolts -1- are positioned within the four centring tabs. |

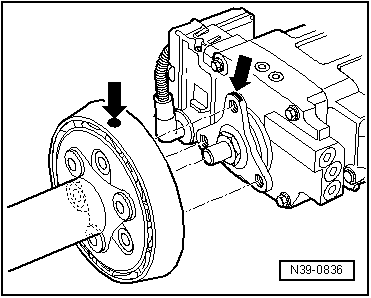

| If the final drive has been renewed: |

| –

| Check oil level in Haldex coupling (4th Generation), check and, top up where applicable, Altea XL 2009 ►, Altea XL Freetrack 2008 ►, Altea XL Freetrack 2009 ►, Alhambra 2011 ► → Chapter. |

| –

| Oil level of the rear final group (4th Generation), check and, top up where applicable, Altea XL 2009 ►, Altea XL Freetrack 2008 ►, Altea XL Freetrack 2009 ►, Alhambra 2011 ► → Chapter. |

| –

| Make the basic adjustment of the headlight using the vehicle diagnostic, testing and information system -VAS 505X-. |

|

|

|

Note

Note Note

Note

Note

Note Note

Note

Note

Note