| t

| Only remove the plugs from the new hydraulic unit once the corresponding brake pipe is fitted. |

| t

| If the plugs are removed from the control unit beforehand, brake fluid could flow out, for which the filling and bleeding of the system could not be guaranteed. |

| On assembling the control unit with the hydraulic unit, make sure that the hydraulic unit valves fit properly into the control unit solenoids. |

| –

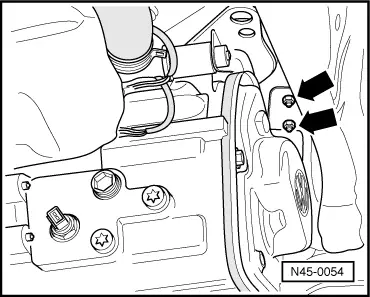

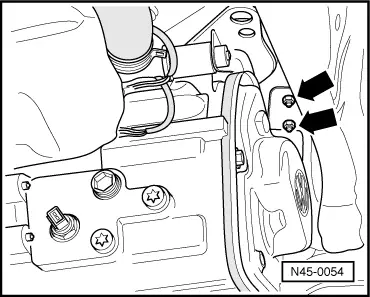

| Secure the control unit to the hydraulic unit with new screws. Tightening torques: max. 4 Nm |

| –

| Connect the hydraulic pump motor connector. |

| –

| Bolt the ABS unit to its support. Tightening torques: 8 Nm |

|

|

|