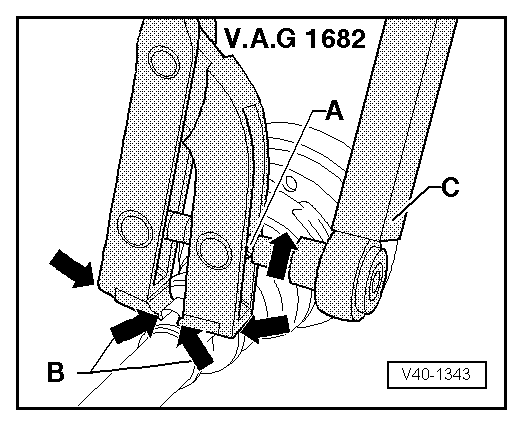

| Tight the larger diametered clamp of the exterior constant velocity joint |

| –

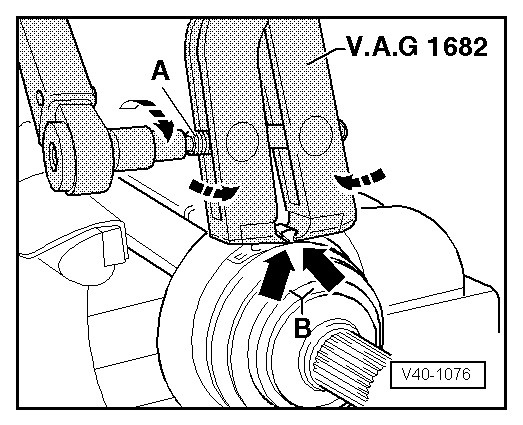

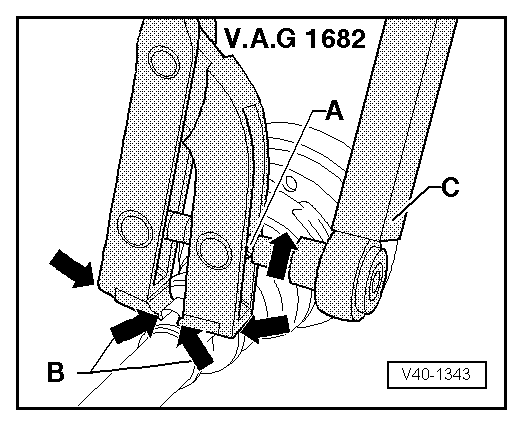

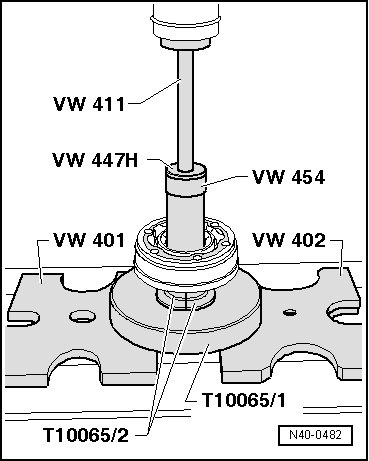

| Position clamp tensioner -V.A.G 1682- as shown in illustration. Ensure that the edges of the tool fit into the corners -arrows B- of the clamp. |

| –

| Tighten clamp by turning spindle with a torque wrench (do not cant pliers). |

Note | t

| Given the firmness of the material (in comparison with the rubber) of the union dustguard, a stainless steel clamp is required, this can only be tightened using the pliers -V.A.G 1682-. |

| t

| Use torque wrench -C- with adjustment range 5 … 50 Nm, (e.g. torque wrench -V.A.G 1331-). |

| t

| Make sure thread of spindle -A- on pliers moves freely. Lubricate with MoS2 grease if necessary. |

| t

| If the thread does not turn easily due to dirt, for example, it will not be possible to tension the clamp to the prescribed torque. |

| t

| Tightening torque: min. 12 Nm |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note