Leon Mk1

| Propeller shaft with constant velocity joint - assembly overview |

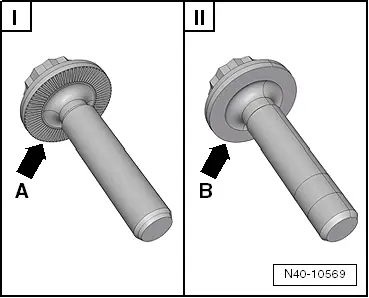

| 1 - | Outer constant velocity joint |

| q | Replace completely |

| q | Removing → Fig. |

| q | Installing: slide onto the half shaft to the limit by tapping with a plastic mallet |

| q | check → Chapter |

| 2 - | Bolt. |

| q | Replace after each removal |

| q | Hexagon bolt = 200 Nm + 180° further |

| q | Loosening and tightening the hex bolt → Chapter |

WARNING

WARNING

|

| 3 - | Circlip |

| q | Replace after each removal |

| q | Insert in groove in shaft |

| 4 - | Thrust washer |

| q | Installation position → Fig. |

| 5 - | Dished spring |

| q | Installation position → Fig. |

| 6 - | Clamp |

| q | Replace after each removal |

| q | Tension → Fig. |

| 7 - | Dust boot |

| q | Ensure that there is no damage or cracks from friction |

| q | Material: Hytrel (polyelastomer) |

| 8 - | Clamp |

| q | Replace after each removal |

| q | Tension → Fig. |

| 9 - | Drive shaft |

| 10 - | Clamp |

| q | Replace after each removal |

| q | Tension → Fig. |

| 11 - | Dustguard for constant velocity joint |

| q | Material: Hytrel (polyelastomer) |

| q | Without breather hole |

| q | Ensure that there is no damage or cracks from friction |

| q | Separate from the constant velocity joint using an awl |

| q | Apply sealing compound (allocation → parts catalogue) on the sealing surface before the dust cover is attached to the constant velocity joint. |

| 12 - | Clamp |

| q | Replace after each removal |

| q | Tension → Fig. |

| 13 - | Locking plate |

| 14 - | Panel |

| q | Drive off carefully with drift |

| q | Apply sealing compound (allocation → parts catalogue) on the sealing surface before the dust cover is attached to the constant velocity joint. |

| q | Adhesive surface must be free of oil and grease! |

| 15 - | Inner constant velocity joint |

| q | Replace completely |

| q | Pressing off → Fig. |

| q | Pressing on → Fig. |

| q | check → Chapter |

| 16 - | Seal |

| q | The surface that is attached to the constant velocity joint should be free of grease and oil |

| 17 - | Circlip |

| 18 - | Panel |

| q | Replace after each removal |

| q | Pressing off → Fig. |

| 19 - | Multi-point socket head bolt |

| q | Initially tighten diagonally to 10 Nm and then tighten diagonally to specified torque. |

| M8 bolt: 40 Nm |

| M10 bolt: 70 Nm |

| q | Always replace bolts after dismounting |