Caution | When removing and installing drive shafts, do not allow them to hang free and stop against joints due to excessive bending. |

|

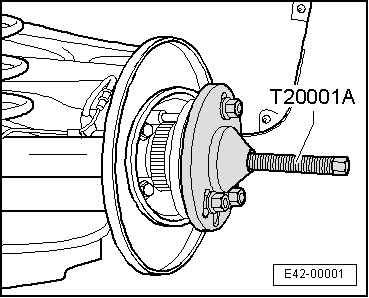

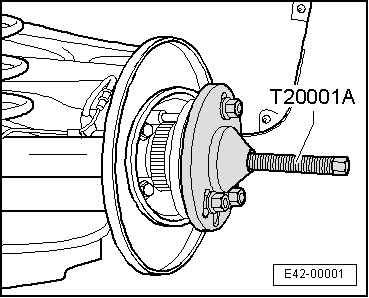

| –

| Release the bolt from the outer side of the half-shaft. |

| t

| Twelve-point head bolt with ribbing → Chapter |

| t

| Twelve-point head bolt without ribbing → Chapter |

Caution | Wheel bearings must not be subjected to load after loosening bolt securing drive shaft at wheel hub. |

| If they have to support the weight of the vehicle they will be damages and their service life will be reduced. |

| It is not permissible to turn drive shaft bolt more than 90° anti-clockwise if vehicle is standing on its wheels. |

| Do not attempt to move the vehicle without the drive shafts fitted; this would result in wheel bearing damage. If a vehicle nevertheless has to be moved, comply with the following: |

| t

| Install an outer joint instead of the drive shaft. |

| t

| Tighten outer joint to 120 Nm. |

|

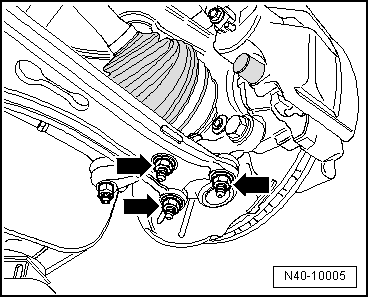

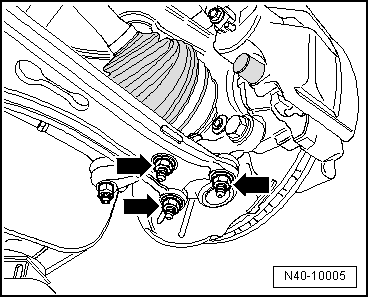

| –

| Unscrew the half-shaft from the flanged shaft /gearbox. |

|

|

|