| Tighten clamp on outer joint |

| –

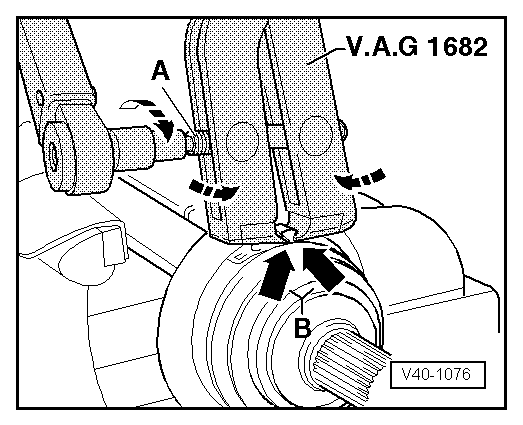

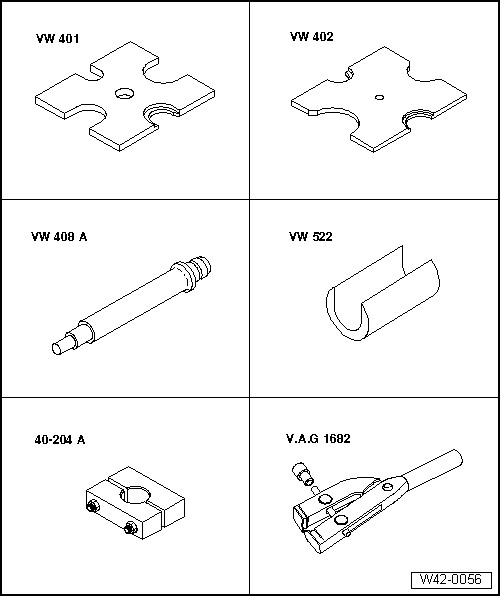

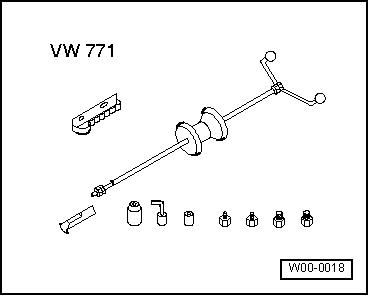

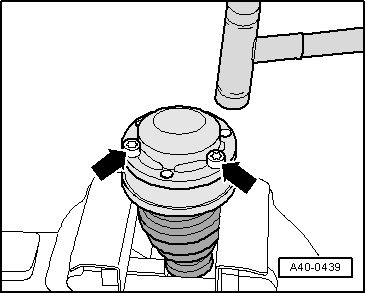

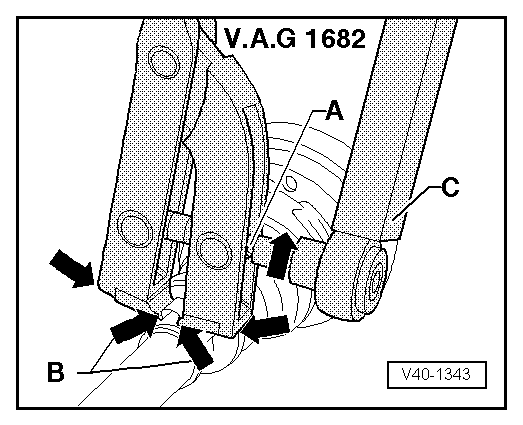

| Apply special pliers-V.A.G 1682- as shown in diagram. Ensure that the edges of the tool fit into the corners -arrows B- of the clamp. |

| –

| Tighten clamp by turning spindle with a torque wrench (do not cant pliers). |

Note | t

| Due to the hard material of the protective boot (compared to rubber) and the necessity of using a stainless steel clamp, it is only possible to tension the clamp with clamp tensioner -V.A.G 1682-. |

| t

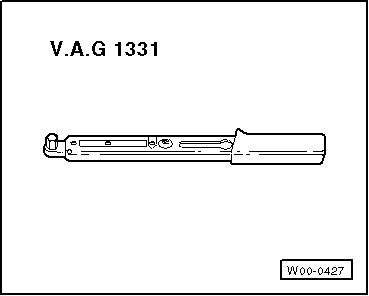

| Tightening torque: 25 Nm. |

| t

| Use torque wrench -C- with adjustment range 5 … 50 Nm, (e.g. torque wrench -V.A.G 1331-). |

| t

| Make sure thread of spindle -A- on pliers moves freely. Lubricate with MoS2 grease if necessary. |

| t

| If the thread is tight (e.g. due to dirt), the required clamping force for the clamp will not be attained although the specified tightening torque is applied. |

|

|

|

Note

Note