Leon Mk1

|

|

|

|

|

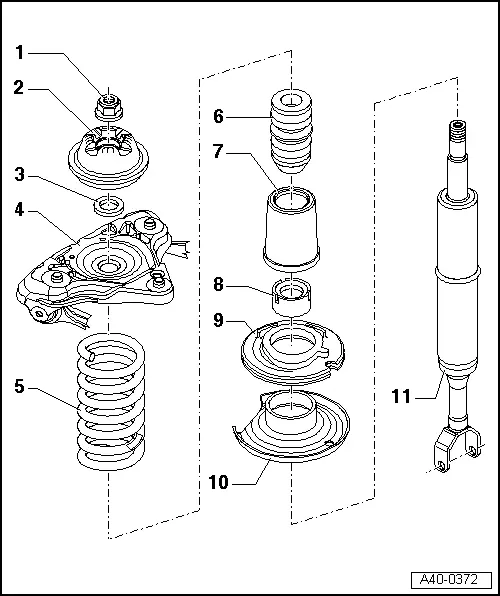

| 1 - | Nut, 50 Nm |

| q | Always replace. |

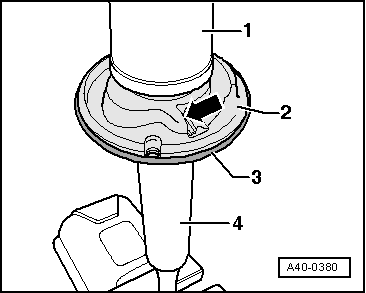

| 2 - | Shock absorber mounting |

| 3 - | Washer |

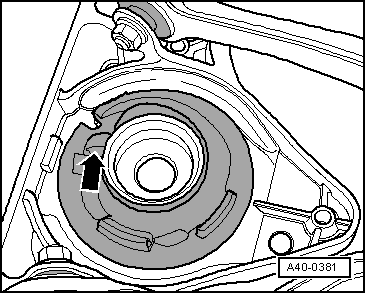

| 4 - | Support buck |

| q | Installation position → Anchor |

| q | Remove and install the coil springs, shock absorbers and mounting bracket as one unit → Chapter |

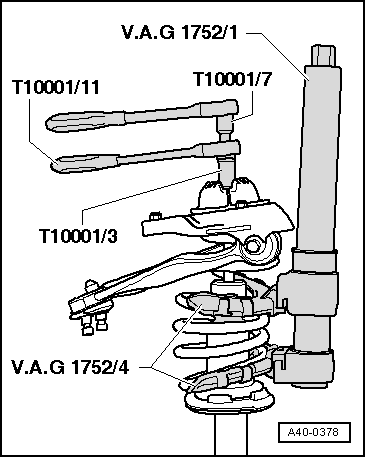

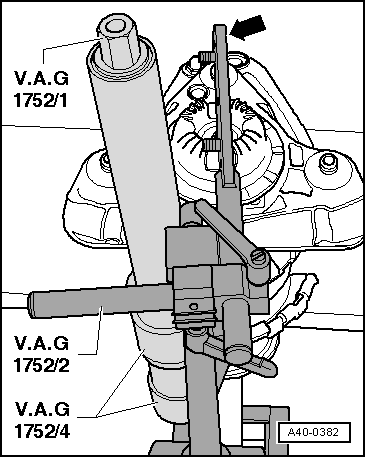

| 5 - | Coil spring |

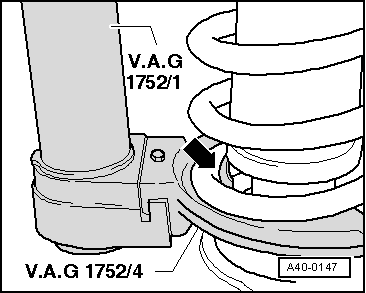

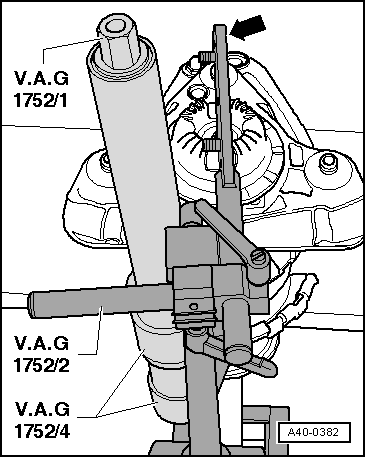

| q | Removing → Fig. |

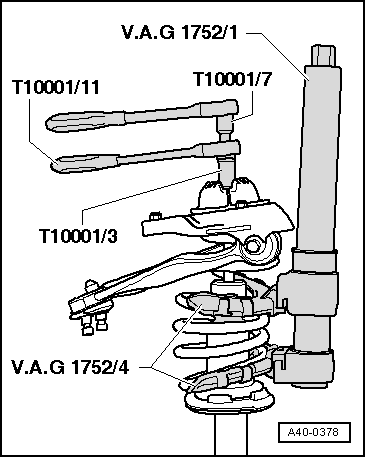

| q | Installing → Fig. |

| q | Observe various chassis versions, see vehicle data carrier. |

| q | Allocation: → Parts catalogue |

| q | Remove and install the coil springs, shock absorbers and mounting bracket as one unit → Chapter |

| 6 - | Additional spring |

| 7 - | Boot |

| 8 - | Protective cap |

| 9 - | Lower spring seat |

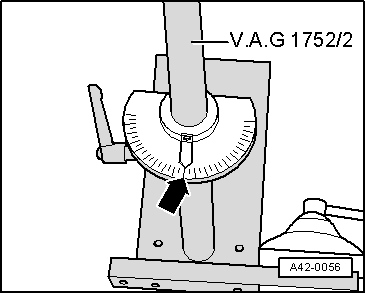

| 10 - | Bottom spring plate |

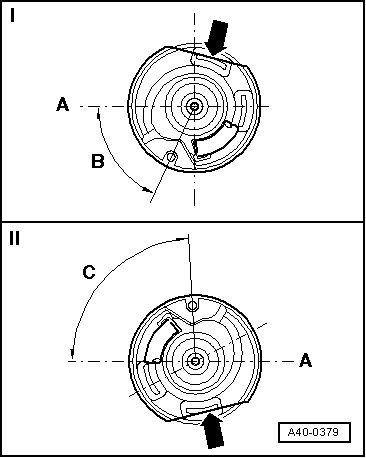

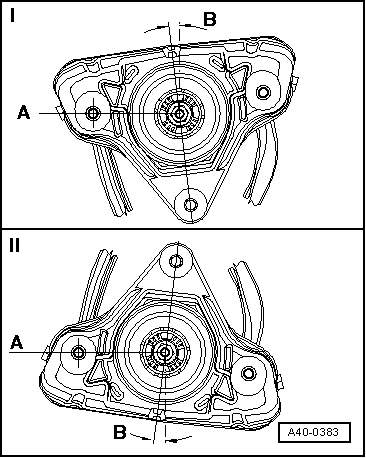

| q | Installation position → Fig. |

| 11 - | Shock absorber |

| q | replace → Fig. |

| q | Observe various chassis versions, see vehicle data carrier. |

| q | Defective shock absorbers must always be degassed and drained before disposal |

| q | Allocation: → Parts catalogue |

| q | Remove and install the coil springs, shock absorbers and mounting bracket as one unit → Chapter |

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WARNING

WARNING