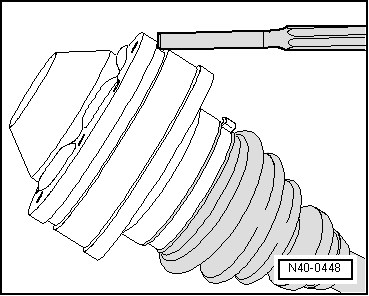

| Tension the clamp of the exterior constant velocity joint |

| –

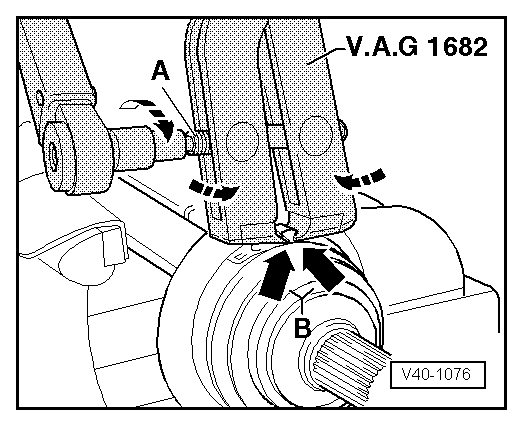

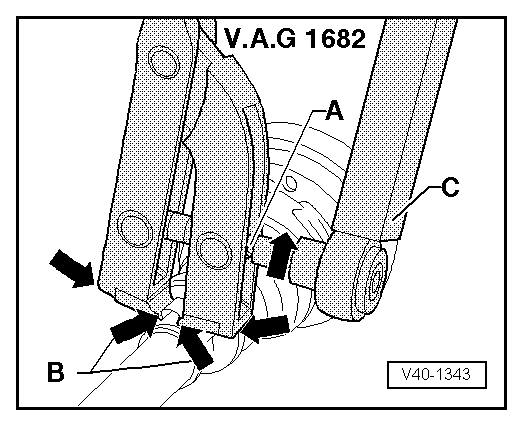

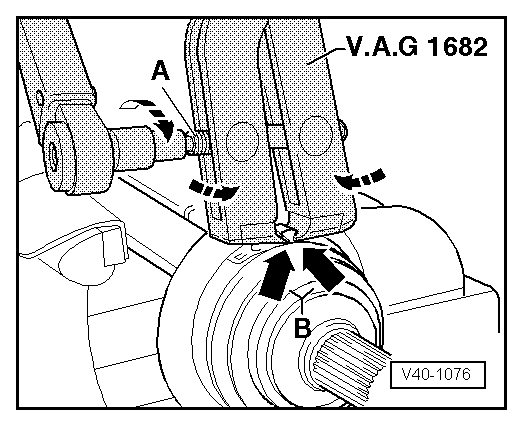

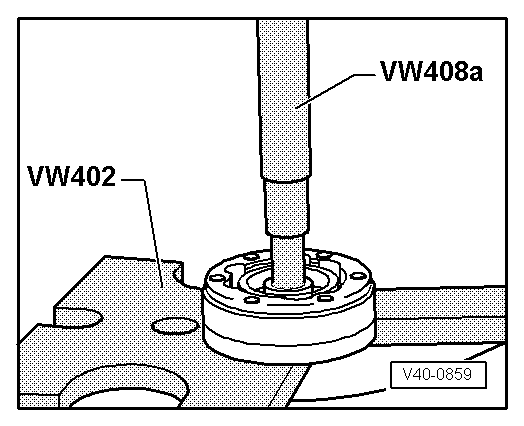

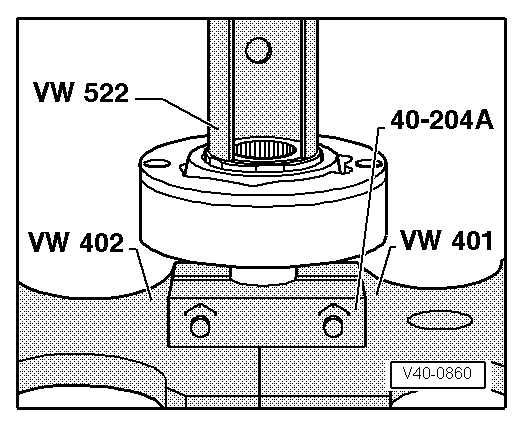

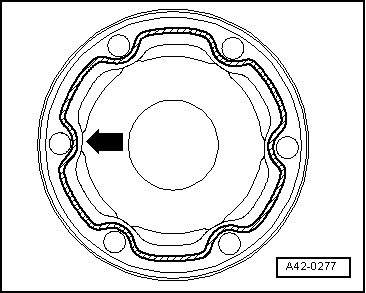

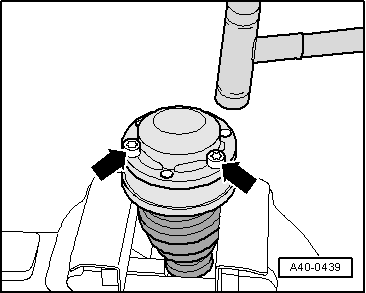

| Apply clamp tensioner-V.A.G 1682- as shown in illustration. Ensure jaws of tensioner lie in corners -arrows B- of ears on O-type clip. |

| –

| Tighten clamp by turning spindle with a torque wrench (do not cant pliers). |

Note | t

| Given the firmness of the material (in comparison with the rubber) of the union dustguard, a stainless steel clamp is required, this can only be tightened using the pliers -V.A.G 1682-. |

| t

| Tightening torque: 25 Nm |

| t

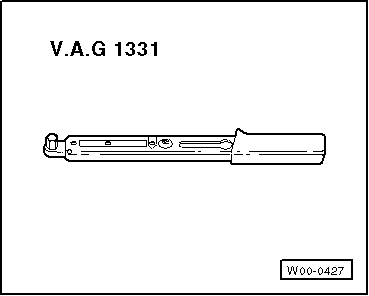

| Use a torque wrench -C- with a range between 5 and 50 Nm (e.g torque wrench -V.A.G 1331-). |

| t

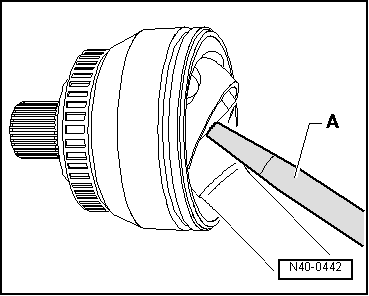

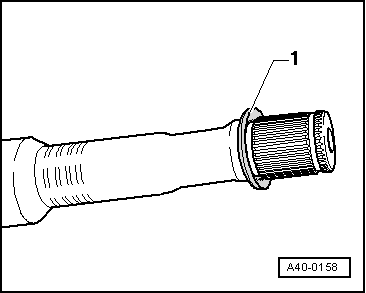

| Check that the spindle thread -A- of the pliers is easily movable; apply grease if necessary. |

| t

| If the thread does not turn easily due to dirt, for example, it will not be possible to tension the clamp to the prescribed torque. |

|

|

|

Note

Note