Leon Mk1

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

| Specified torques |

| Component | Tightening torque | ||||

Swivel joint to cast steel suspension link

| 60 Nm | ||||

Swivel joint to sheet steel or forged aluminium suspension link

| 100 Nm | ||||

Anti-roll bar to coupling rod

| 65 Nm | ||||

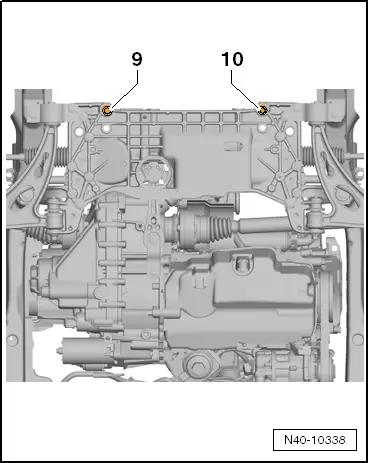

Suspension link to subframe

| 70 Nm + 180° | ||||

Steering box to subframe

| 50 Nm + 90° | ||||

Track rod ball joint to wheel bearing housing

| Tighten to 100 Nm, then loosen (turn back) 180° and retighten to 100 Nm | ||||

Universal joint to steering box

| 30 Nm | ||||

| Exhaust system bracket to subframe → Engine; Rep. gr.26 | |||||

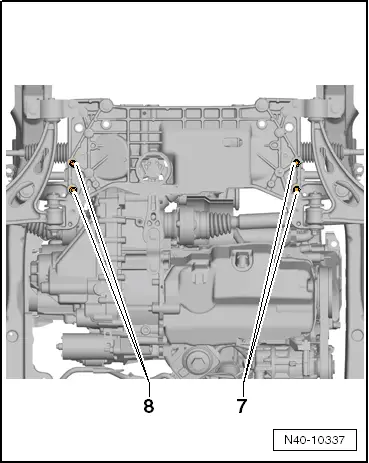

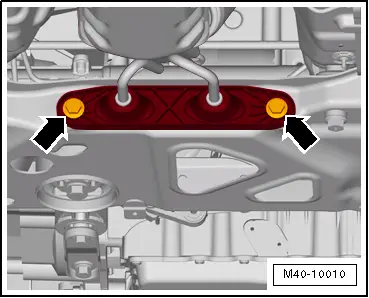

| Specified torques, subframe to body |

| Bolt. | Tightening torque | ||

M12 x 1.5 x 90

| 70 Nm and then turn 180° further | ||

M12 x 1.5 x 100

| 70 Nm and then turn 180° further |

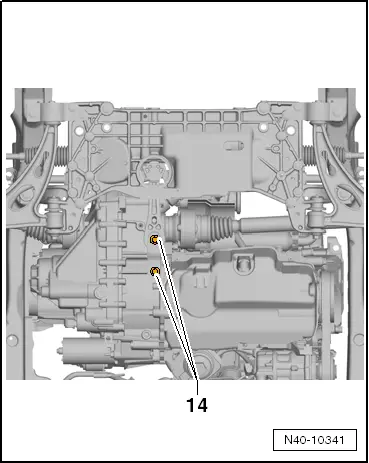

| Specified torques for pendulum support to gearbox |

| Bolt. | Tightening torque | ||

M10 x 35

| 50 Nm and then turn 90° further | ||

M10 x 75

| 50 Nm and then turn 90° further | ||

M12 x 1.5 x 85 ; M12 x 1.5 x 50

| 60 Nm and then turn 90° further |

|

Caution

Caution