| –

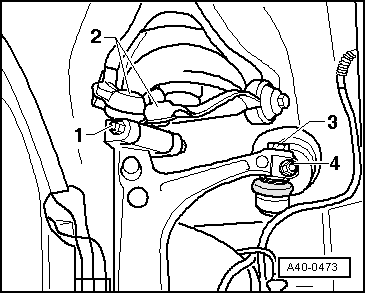

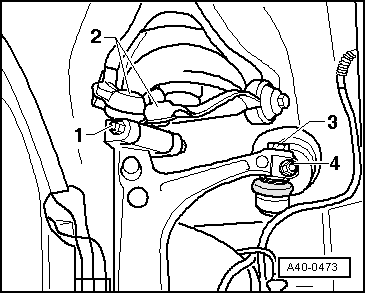

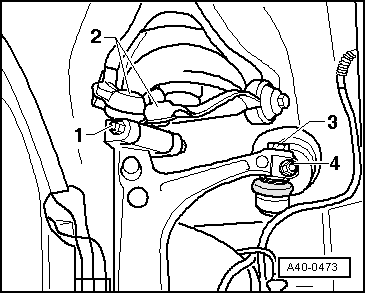

| Loosen nut -1-, take out hexagon bolt and pull out both upper links -2- upwards. |

| Do not attempt to enlarge slots in wheel bearing housing using a chisel or similar. |

Note | Do not loosen bolts -3- and -4- as this would change the front axle alignment. |

| –

| Swing wheel bearing housing out to the side. |

| –

| Set the drive shaft on wheel bearing assembly. |

| –

| Install both upper transverse control arms, insert new bolt and tighten nut to specified tightening torque → Item. When tightening the transverse link press towards wheel bearing assembly as far as possible. |

| –

| Screw propeller shaft into flanged shaft/gearbox connection and tighten bolts to specified tightening torque → Item. |

| –

| Screw in the outer joint of the drive shaft. |

Note | The wheels must not be in contact with the ground when initially tightening the bolt securing the outer drive shaft joint; otherwise the wheel bearing can be damaged. |

| The following flow needs a second mechanic. |

| –

| 1. mechanic: He sits in the vehicle and operates the brake. |

| –

| 2. mechanic: He tightens the hexagon bolt of the drive shaft with the pre-tightening torque. |

| –

| Fit wheel and lower vehicle onto the ground. |

| –

| Turn bolt securing drive shaft a further +180°. (Only turn the bolt through this additional angle when the vehicle is standing on wheels: accident risk). |

|

|

|

Note

Note Note

Note

Note

Note Note

Note