| Tightening torque: 50 Nm + 45º (1/8 turn) tighten again |

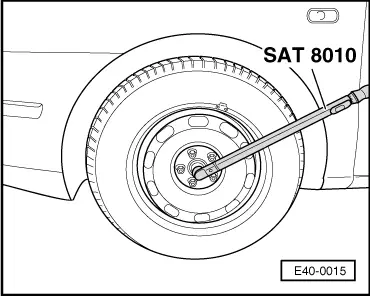

| If the tool is not available, the dodecagonal nut can be tightened using the following method. |

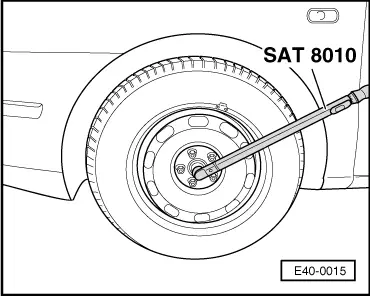

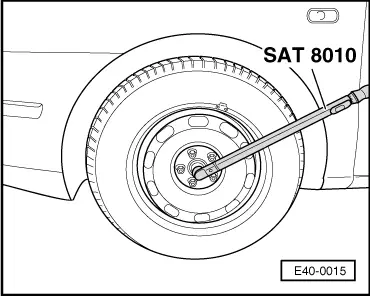

| –

| Lower the vehicle until the wheels touch the ground. |

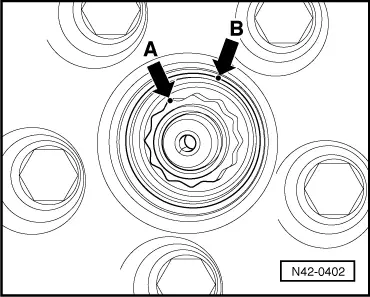

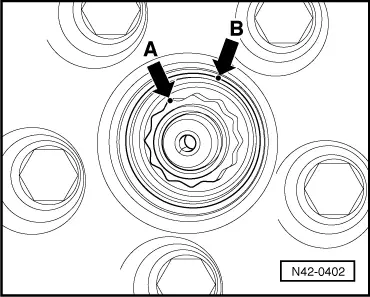

| –

| Tighten the dodecagonal nut using a torque of 200 Nm and loosen by one turn. |

| –

| Turn the nut to a torque of 50 Nm to begin. |

|

|

|