Leon Mk1

|

|

|

|

|

|

|

Note

Note

|

|

|

|

| Specified torques |

| Component | Tightening torque | ||||

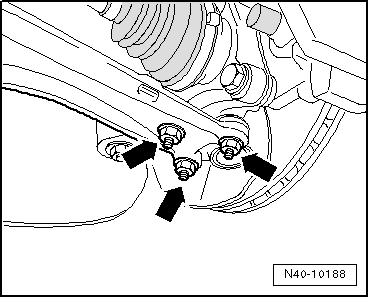

Swivel joint to cast steel suspension link

| 60 Nm | ||||

Swivel joint to sheet steel or forged aluminium suspension link

| 100 Nm | ||||

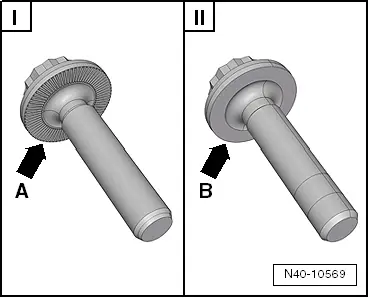

Drive shaft to wheel hub „twelve-point head bolt with ribbing“

| 70 Nm + 90° | ||||

Drive shaft to wheel hub „twelve-point head bolt without ribbing“

| 200 Nm + 180° | ||||

Drive shaft to flange shaft on gearbox „M10 multi-point socket“

| 70 Nm

|

Caution

Caution