| –

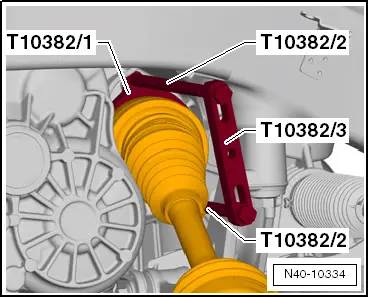

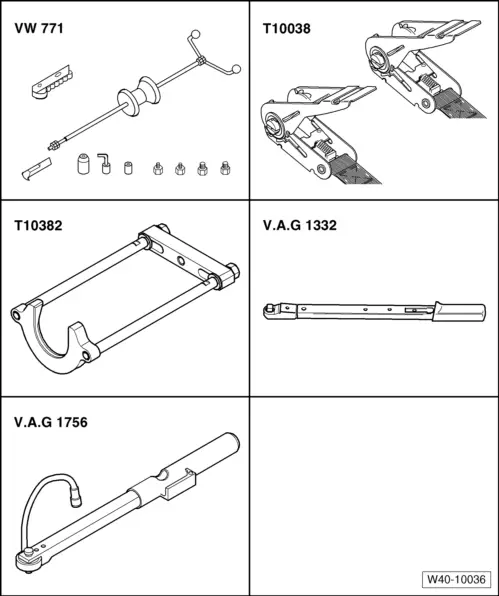

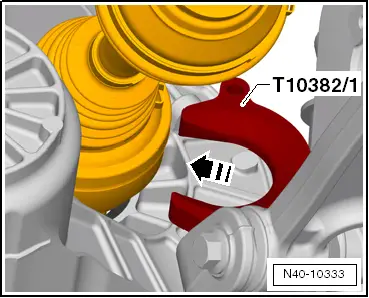

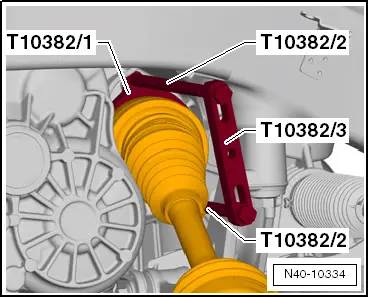

| Install spindles -T10382/2- and traverse -T10382/3- on puller plate -T10382/1-. |

| –

| Install multi-purpose tool -VW 771- on traverse -T10382/3-. |

| –

| Pull out drive shaft with a couple of strikes of multi-purpose tool -VW 771-. |

| –

| Remove drive shaft from vehicle. |

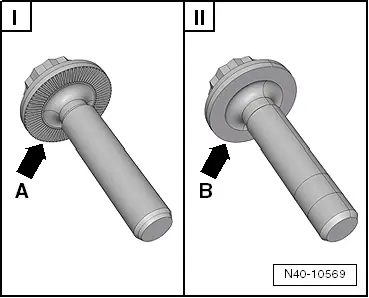

| Remove any paint residues and/or corrosion on thread and splines of outer joint. |

| –

| Insert new retaining ring in groove in stub shaft on gearbox. |

| –

| Lightly grease splines of stub shaft with universal grease -G 060 735 A2-. |

| –

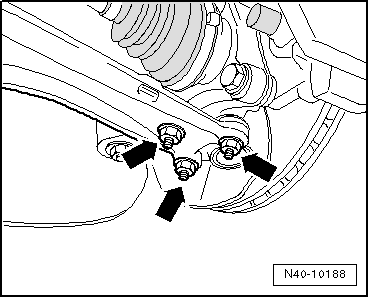

| Mesh outer and inner splines of gearbox and constant velocity slip joint. |

| –

| Slide drive shaft into constant velocity joint to stop by hand. |

| –

| Now push constant velocity joint onto stub shaft of gearbox with a »sudden, hard push«. |

Note | Never use a hammer or other driving tools. |

| –

| Check that constant velocity slip joint is securely seated by pulling constant velocity slip joint against resistance of retaining ring. |

Caution | For this test, it is only permitted to pull on constant velocity slip joint and not on drive shaft. |

|

| –

| Remove tensioning strap -T10038-. |

| –

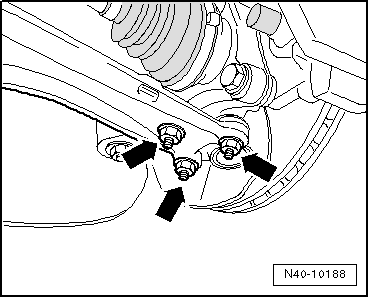

| Guide outer joint into wheel hub splines as far as possible. |

|

|

|

Note

Note

Note

Note

Caution

Caution