| –

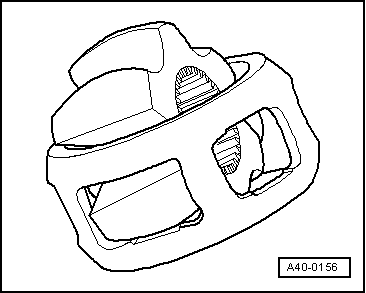

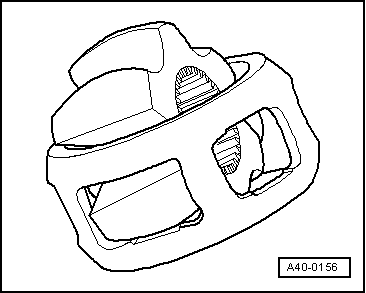

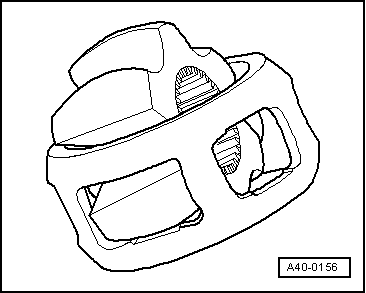

| Swivel one segment of the hub into one of the cage openings. |

| –

| Remove the hub from the cage. |

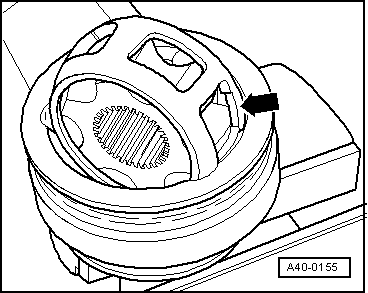

| The six balls for each joint belong to a tolerance group. Check stub axle, hub, cage and balls for small indentations (pitting) and traces of seizing. Too much circumferential backlash in the joint becomes noticeable during load change jolts; in such cases, the joint must be renewed. Smooth areas and ball running marks do not constitute grounds for joint replacement. |

| –

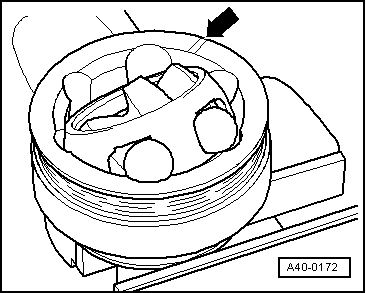

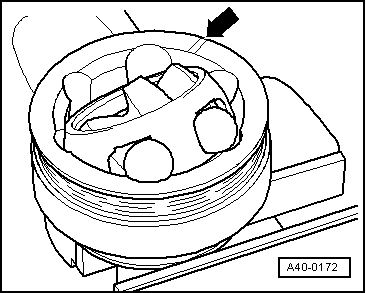

| Fit cage with hub into joint body. |

Note | Make sure cage is inserted in correct position (i.e. sides facing in same direction as original position). |

| –

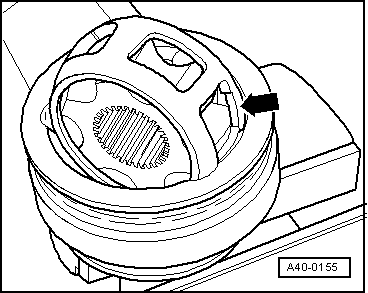

| Press in opposing balls one after the other; the original position of the hub relative to the cage and joint body must be restored. |

| –

| Pack grease into joint body; refer to for quantity and type of grease. |

|

|

|

Note

Note

Note

Note