Leon Mk1

| Removing and installing suspension strut |

| Special tools and workshop equipment required |

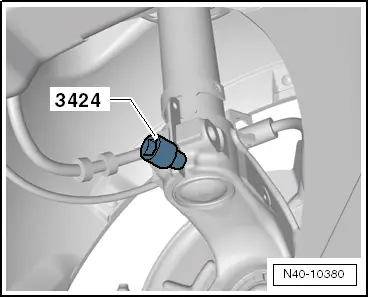

| t | Spreader -3424- |

| t | Torque wrench -V.A.G 1332- |

| t | Engine/gearbox jack -V.A.G 1383 A- |

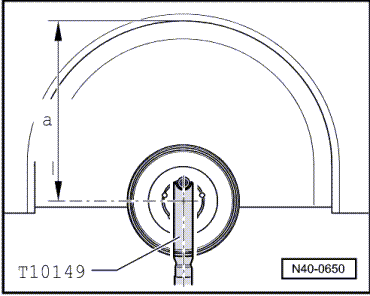

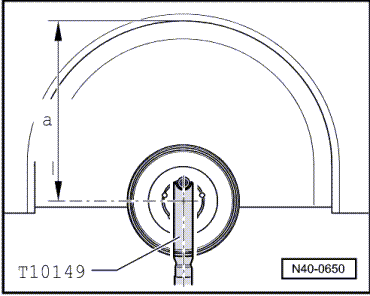

| t | Mounting -T10149- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

Note

Note

|

|

| Specified torques |

| Component | Tightening torque | ||||

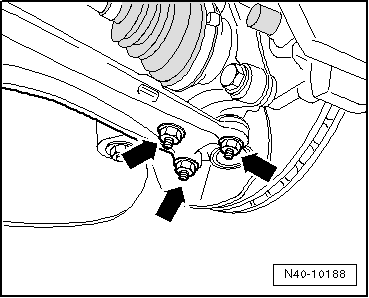

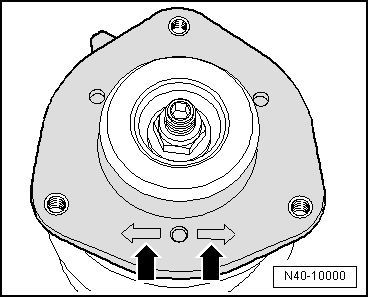

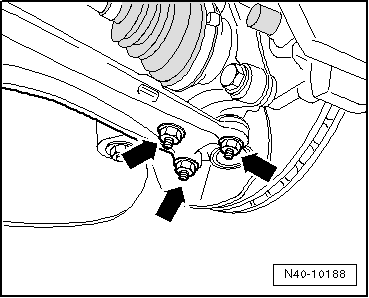

Suspension strut to wheel bearing housing

| 70 Nm + 90° | ||||

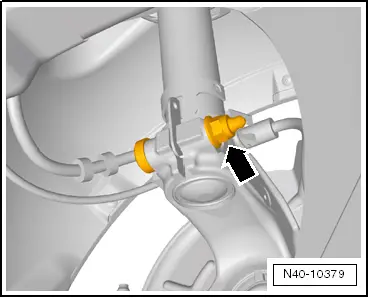

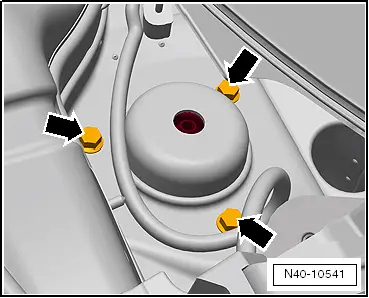

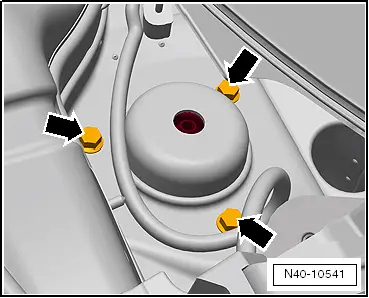

Suspension strut to body (suspension turret)

| 15 Nm + 90° | ||||

Swivel joint to cast steel suspension link

| 60 Nm | ||||

Swivel joint to sheet steel or forged aluminium suspension link

| 100 Nm | ||||

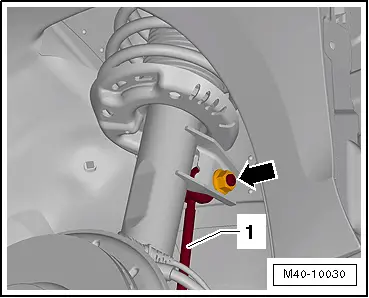

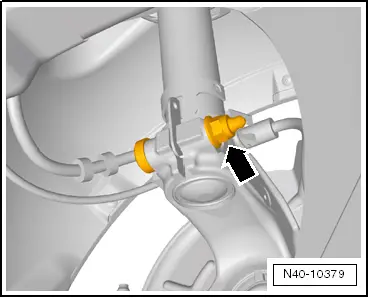

Coupling rod to suspension strut

| 65 Nm | ||||

Drive shaft to hub

| 70 Nm + 90° |

Caution

Caution WARNING

WARNING