Leon Mk1

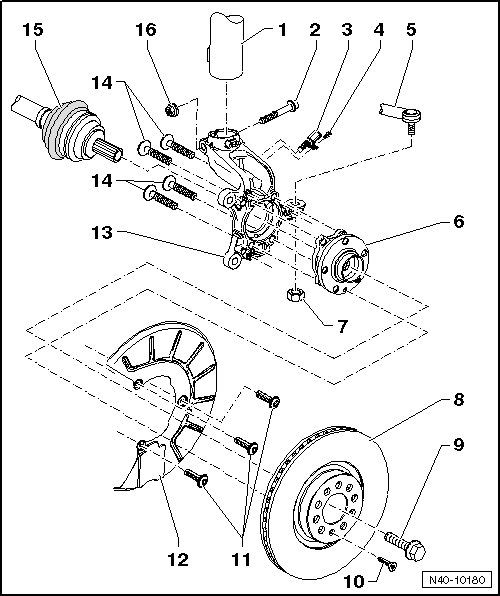

| Wheel bearing assembly: Assembly overview |

| 1 - | Suspension strut |

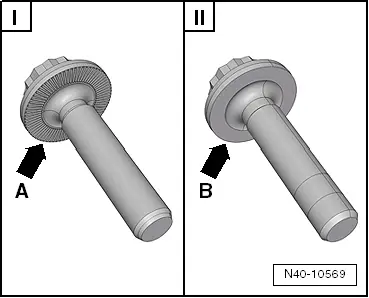

| 2 - | Multi-point socket head bolt |

| q | The end of the hexagonal bolt should face in the direction of travel of the vehicle |

| 3 - | Front left speed sensor -G47- / front right speed sensor -G45- |

| q | Can be tested in guided fault finding using → Vehicle diagnostic tester |

| q | Before inserting speed sensor, clean inner surface of fitting hole and coat with lubricating paste -G 000 650-. |

| 4 - | Hexagon socket head bolt |

| q | M6 x 16 |

| q | 8 Nm |

| 5 - | Track rod ball joint |

| 6 - | Wheel hub with wheel bearing |

| q | The ABS sensor ring is fitted in the wheel hub |

| q | Different versions available |

| q | Assignment → Electronic parts catalogue „ETKA“ |

| 7 - | Nut |

| q | M12 x 1.5 |

| q | Tighten to 100 Nm, then loosen (turn back) 180° and retighten to 100 Nm |

| q | Self-locking |

| q | Always renew if removed |

| 8 - | Internally ventilated brake disc |

| 9 - | Bolt. |

| q | Different versions available |

| q | Assignment → Electronic parts catalogue „ETKA“ |

WARNING

WARNING

|

| q | Always renew if removed |

| 10 - | Bolt. |

| q | Torque setting → Brake systems; Rep. gr.46. |

| 11 - | Multi-point socket head bolt |

| q | M6 x 12 |

| q | 12 Nm |

| 12 - | Cover plate |

| 13 - | Wheel bearing housing |

| q | removing and installing → Chapter |

| q | With bolted-on brake carrier. |

| q | If wheel bearing housing is renewed, wheels must be aligned → Chapter |

| 14 - | Multi-point socket head bolt |

| q | M12 x 1.5 x 45 |

| q | 70 Nm and then turn 90° further |

| q | Always renew if removed |

| 15 - | Drive shaft |

| q | removing and installing → Chapter |

| 16 - | Nut |

| q | M12 x 1.5 x 80 |

| q | 70 Nm and then turn 90° further |

| q | Self-locking |

| q | Always renew if removed |