Leon Mk1

|

|

|

|

|

|

|

|

|

| Specified torques |

| Component | Tightening torque | ||

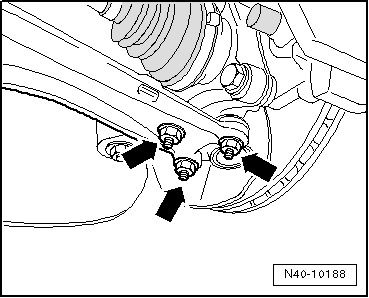

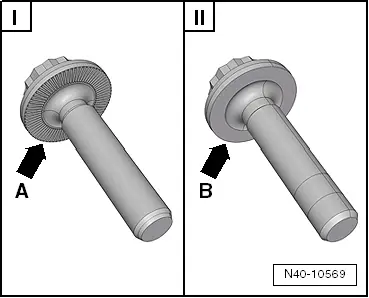

Drive shaft to wheel hub „twelve-point head bolt with ribbing“

| 70 Nm + 90° | ||

Drive shaft to wheel hub „twelve-point head bolt without ribbing“

| 200 Nm + 180° | ||

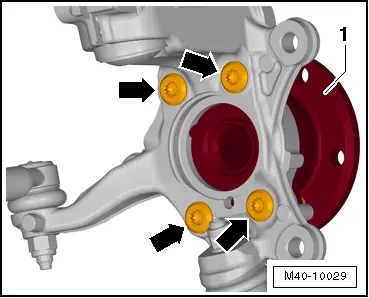

Wheel hub with wheel bearing to wheel bearing housing

| 70 Nm + 90° |

Caution

Caution