Leon Mk1

| Removing and installing wheel bearing housing |

| Special tools and workshop equipment required |

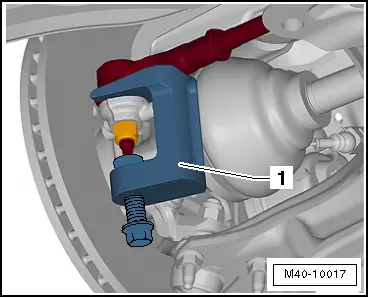

| t | Ball joint puller -3287A- |

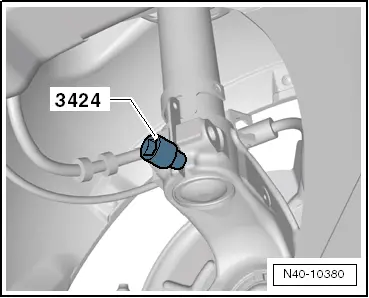

| t | Spreader -3424- |

| t | Ball joint puller -T10187- |

| t | Torque wrench -V.A.G 1332- |

| t | Engine/gearbox jack -V.A.G 1383 A- |

| t | Angle wrench -V.A.G 1756- |

|

|

|

|

|

|

|

Note

Note

|

|

|

|

| Specified torques |

| Component | Tightening torque | ||

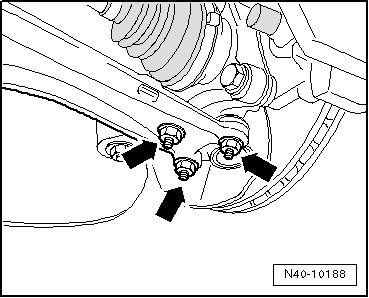

Suspension strut to wheel bearing housing

| 70 Nm + 90° | ||

Swivel joint to cast steel suspension link

| 60 Nm | ||

Swivel joint to sheet steel or forged aluminium suspension link

| 100 Nm | ||

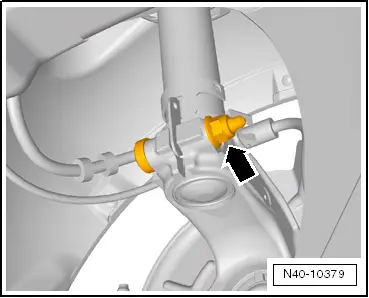

Track rod ball joint to wheel bearing housing

| Tighten to 100 Nm, then loosen (turn back) 180° and retighten to 100 Nm | ||

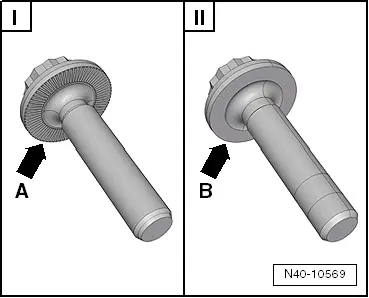

Drive shaft to wheel hub „twelve-point head bolt with ribbing“

| 70 Nm + 90° | ||

Drive shaft to wheel hub „twelve-point head bolt without ribbing“

| 200 Nm + 180° |

Caution

Caution