Leon Mk1

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

| Specified torques |

| Component | Tightening torque | ||||

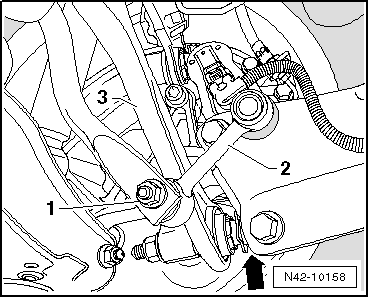

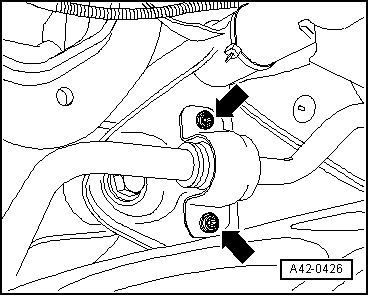

Track rod to wheel bearing housing

| 130 Nm and then turn 90° further | ||||

Track rod to subframe

| 90 Nm and then turn 90° further | ||||

Anti-roll bar to subframe

| 25 Nm and then turn 45° further | ||||

Anti-roll bar to coupling rod

| 45 Nm |

WARNING

WARNING