Leon Mk1

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Specified torques |

| Component | Tightening torque | ||

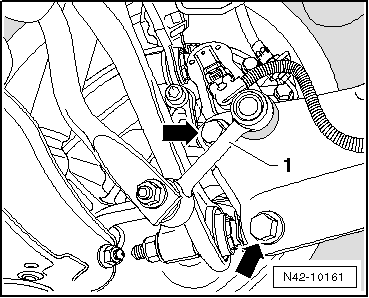

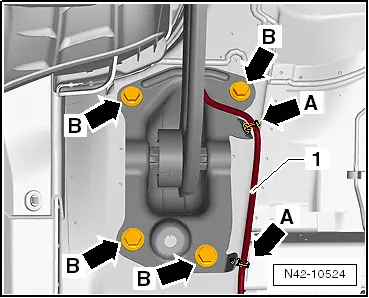

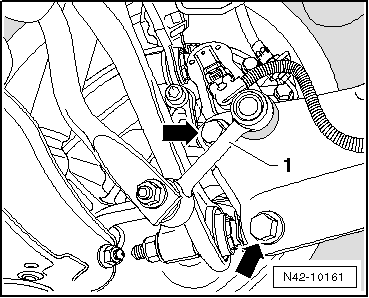

Trailing arm to wheel bearing housing

| 90 Nm and then turn 45° further | ||

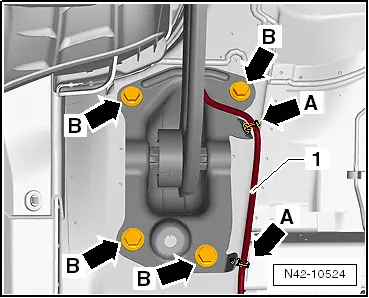

Trailing arm to mounting bracket

| 90 Nm and then turn 90° further | ||

Mounting bracket to body

| 50 Nm and then turn 45° further | ||

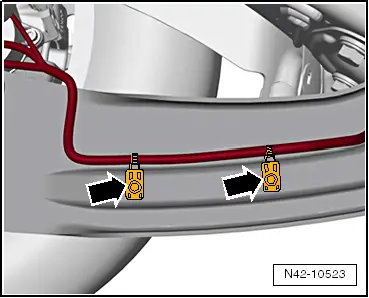

Coupling rod to trailing arm.

| 40 Nm |