| –

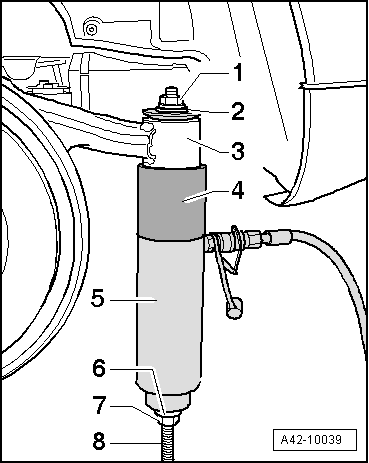

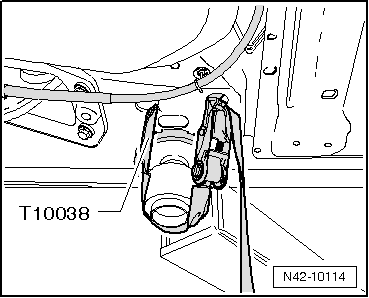

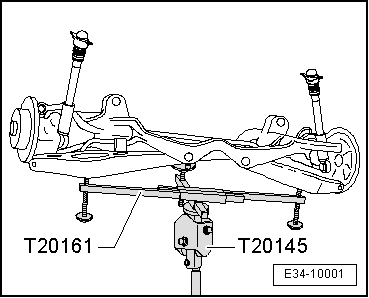

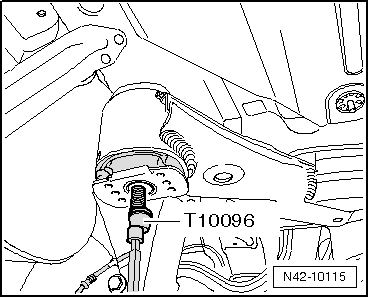

| Set up special tools as shown in figure. |

| 5 - | Hydraulic press -VAS 6178- |

| –

| Take up play in special tools. |

| –

| Pull out bonded rubber bush by actuating pump. |

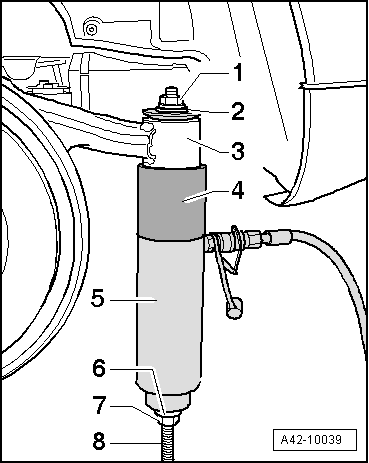

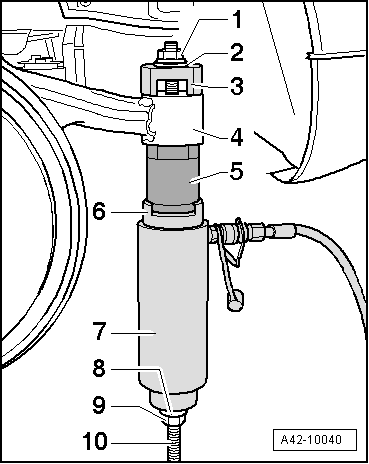

| Insert the front or rear bonded rubber bush. |

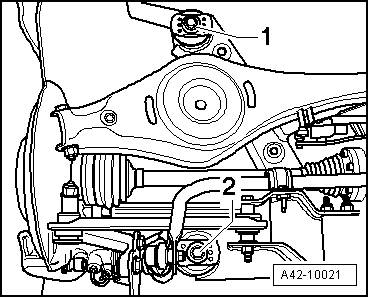

| Installation is carried out in reverse order. During this work it is necessary to observe the following: |

| The front and rear bearings are of somewhat different sizes. When fitting, the correct allocation must be observed → Parts catalogue . |

| Fit the bonded rubber bearing in the correct position; for this, take note of the mark on the subframe. |

|

|

|

Note

Note

WARNING

WARNING