| –

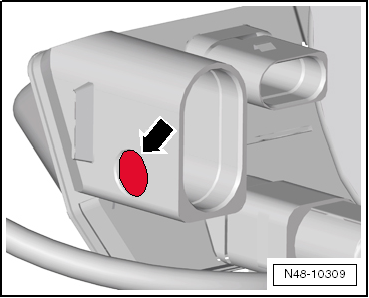

| Check that white pressure diaphragm -arrow- is clean and undamaged. |

| –

| Clean pressure diaphragm carefully if necessary. |

Note | Renew steering box if pressure diaphragm is damaged. |

| The threaded bushings of the steering box should sit well in the openings of the consoles. |

Note | t

| Coat seal on steering box with suitable lubricant, e.g. soft soap, before installing steering box. |

| t

| After fitting the steering box to the universal joint, make sure that the seal is not kinked when lying against the assembly plate and that the opening to the footwell is correctly sealed. Otherwise, there may be noise or water may get in. |

| t

| Ensure sealing surfaces are clean. |

| Before inserting subframe bolts, position steering box on subframe and insert bolts for steering box and anti-roll bar. |

| –

| Bolt universal joint to steering box. |

|

|

|

Note

Note Note

Note

Caution

Caution