Note | t

| Raise the vehicle using only the specially designed sockets. |

| t

| Do not remove the wheel hub covers for alloy wheels using a screwdriver; use the specially designed tool (extraction hook included with the vehicle tools). |

| t

| To loosened the wheel bolts, use a tube spanner of the correct size. Do not use tube spanners that have been damaged or twisted. |

| t

| Do not use a percussion screwdriver to loosen anti-theft wheel bolts (locked bolts). |

| t

| Keep the wheel bolts clean. |

DANGER! | The correct seating of the wheels and wheel bolts is only guaranteed if the checks and instructions below are followed. |

|

| The following checks and instructions should be carried out while the wheel rim is dismounted. |

| –

| Check that contact surfaces on brake disc/wheel hub or brake disc/brake drum and wheel (rim) are free of corrosion and dirt → Chapter. |

| –

| Remove any oil, grease or rust. |

| –

| Check that the centring hole in the wheel rim and the centring flange on the wheel hub are free of corrosion and dirt. → Chapter |

| –

| If necessary, remove any oil, grease or rust and re-establish corrosion protection using a wax spray → Parts catalogue in the centre zone. |

Note | t

| Wax spray must not enter into contact with elements of the brake system. |

| t

| Any rust or dirt which drops between brake disc and wheel hub on removal should be blown out with compressed air. |

DANGER! | Use eye protection glasses when working with compressed air. |

|

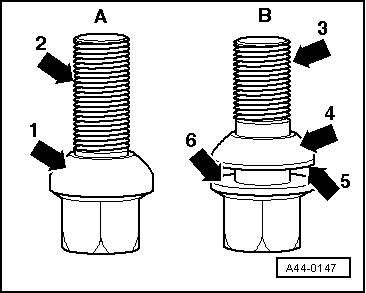

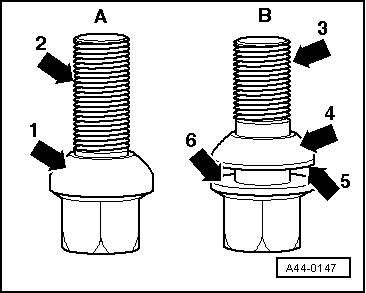

| The rim support cones and the wheel bolts must be free from rust and dirt. |

| –

| Soiled wheel rim support cones must be cleaned with a lint free cloth. |

| –

| Ensure that the wheel bolts and the hub bolt holes are free from rust and dirt. |

| –

| Clean soiled wheel bolts in the area of the cones and the threads using a metal brush. |

Note | Replace heavily corroded or rusty wheel nuts. |

|

|

|

Note

Note Note

Note Note

Note Note

Note

Note

Note Note

Note Note

Note Note

Note