Leon Mk1

| Removing and installing drive shafts on vehicles with automatic gearbox 099 and four-wheel drive |

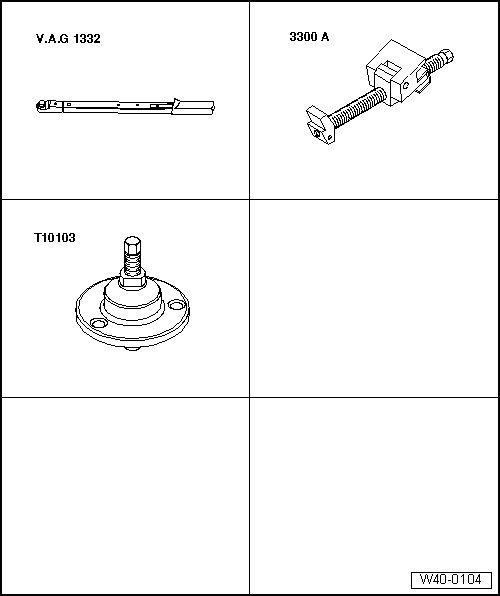

| Special tools and workshop equipment required |

| t | Torque wrench -V.A.G 1332- |

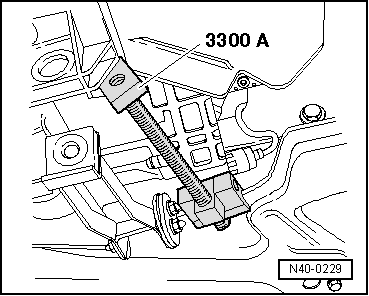

| t | Engine support -3300 A- |

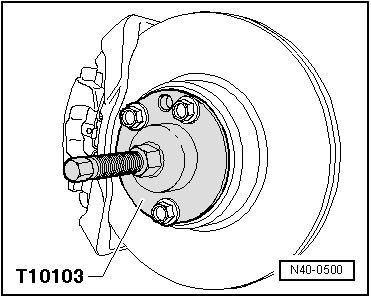

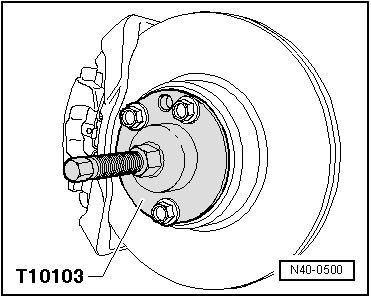

| t | Remover -T10103- |

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

| Specified torques |

| Bolt | Specified torque | ||||

| Swivel joint to wheel bearing housing | 55 Nm | ||||

Drive shaft to hub

| 150 Nm + 90° further | ||||

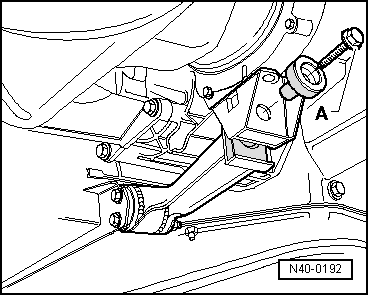

Drive shaft to flange shaft/gearbox

| 70 Nm

| ||||

| Wheel bolts to wheel hub | → Chapter |