| The wheel bearings must not be subjected to load when the hexagon bolt has been loosened. |

| If wheel bearings are loaded with weight of vehicle, bearing will be damaged. This reduces the service life of the wheel bearing. |

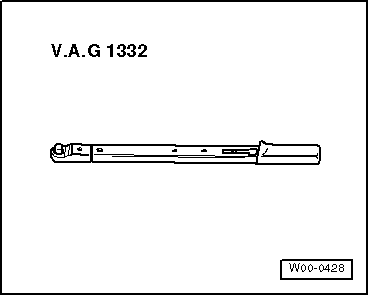

| If a vehicle has to be moved after the drive shaft has been removed, first install an outer joint instead of the drive shaft and tighten to 50 Nm because otherwise the wheel bearing will be damaged. |

| –

| Lift vehicle far enough to take weight off front wheels. |

| –

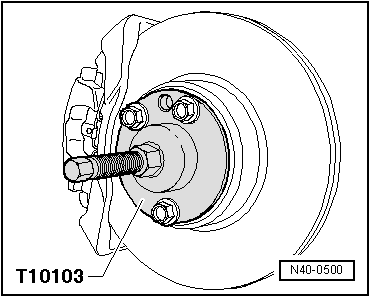

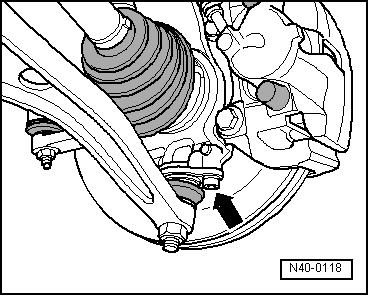

| Remove hexagon bolt for drive shaft. |

| –

| Remove wheel and raise vehicle. |

| –

| Remove noise insulation tray. |

| –

| Unbolt drive shaft from gearbox flange shaft. |

|

|

|

Note

Note