| t

| Hot air blower -VAS 5179- or |

| t

| Hot air blower -V.A.G 1416- or |

| t

| Hot air blower -VAS 1978/14- |

Note! | t

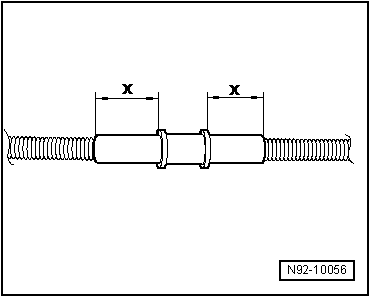

| Repair points must not be subjected to pulling or bending forces. |

| t

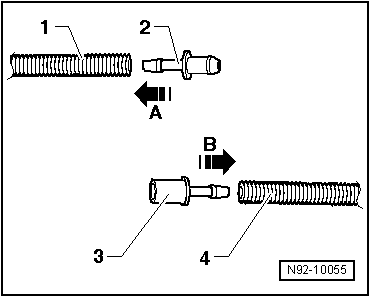

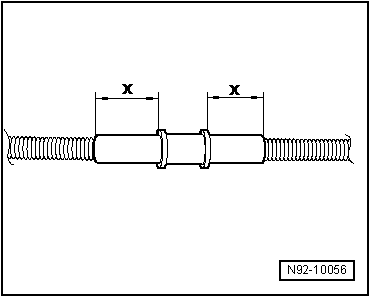

| If the damaged section is longer than 20 mm, a new piece of corrugated pipe must be used and the procedure described below must be performed twice. |

|

|

|

Note!

Note!

Note!

Note!