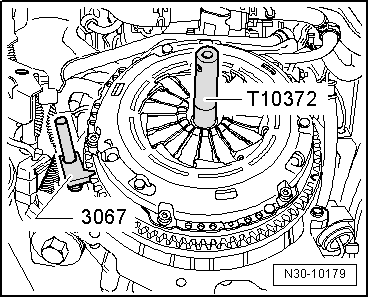

| Installation is carried out in the reverse order, noting the following: |

Note | t

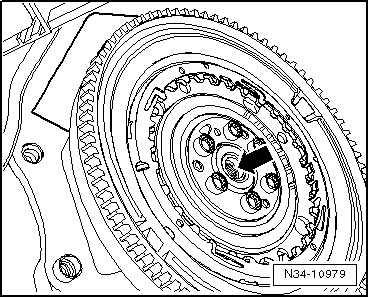

| Check if the centring sleeves are installed in the engine for the purpose of centring the engine with the gearbox and insert these if they are not installed. |

| t

| If dowel sleeves are not fitted, difficulties shifting gears, clutch problems and possible noises from the gearbox (rattling of gears which are not engaged) could occur. |

|

|

|

Note

Note

Note

Note