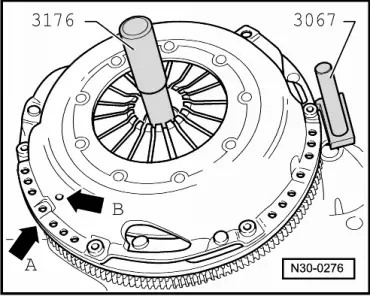

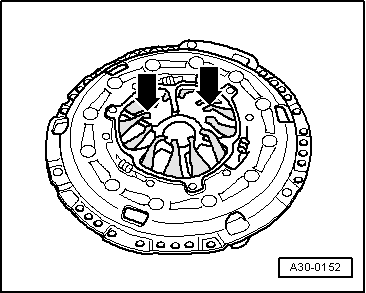

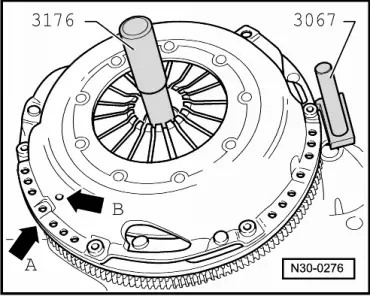

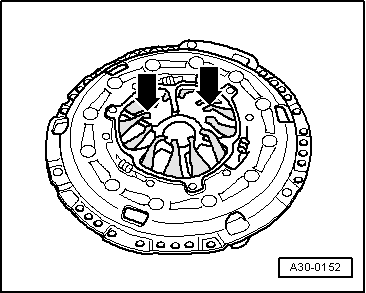

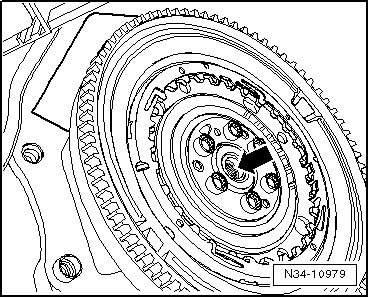

| Checking position of adjustment mechanism (new pressure plates only) |

| l

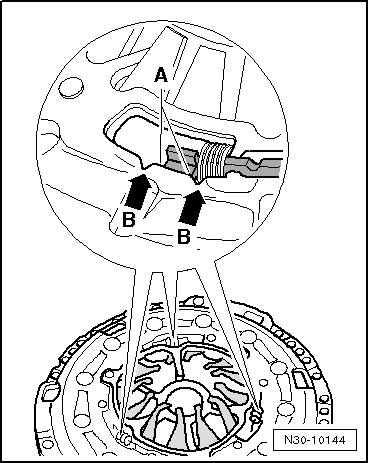

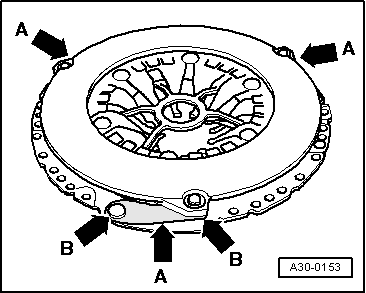

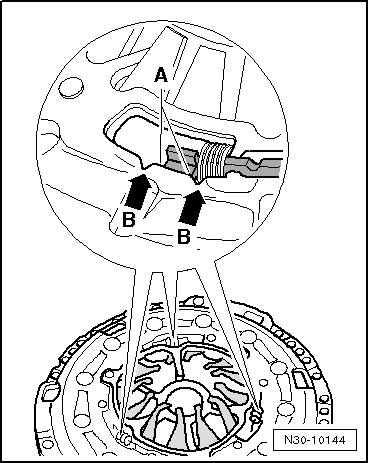

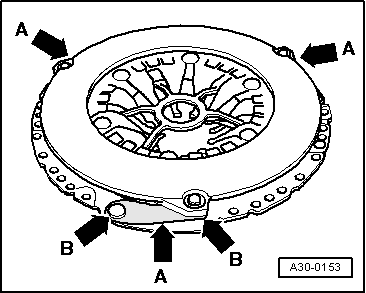

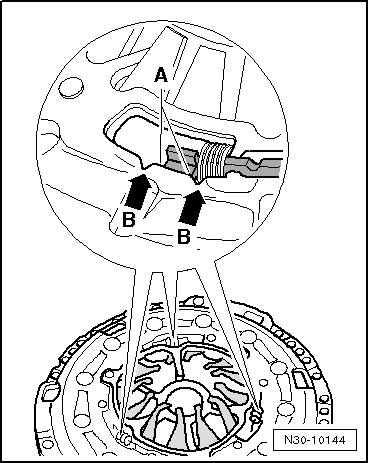

| The two edges -A- of the adjuster ring should be located between the two notches -arrows B-. |

| l

| If the adjuster ring is in a different position on a new pressure plate, the pressure plate and clutch plate must not be installed. |

| l

| The adjuster ring may take up a position outside the notches in used clutches. |

Note | t

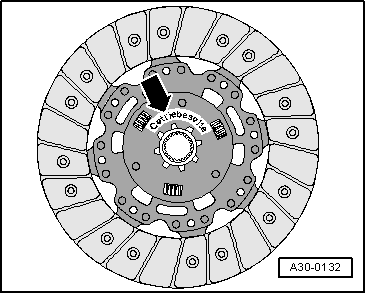

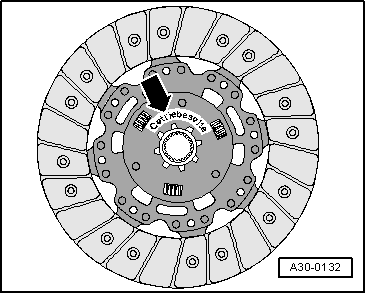

| Renew clutch plate and pressure plate if riveted joints are damaged or loose. |

| t

| Renew pressure plate and clutch plate together only. |

| t

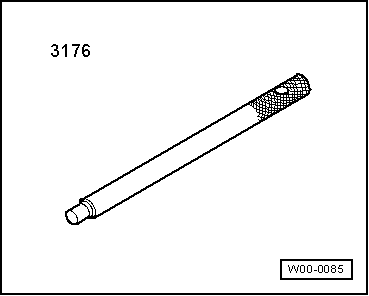

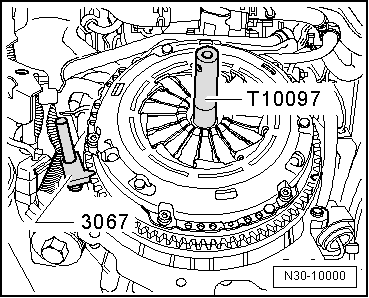

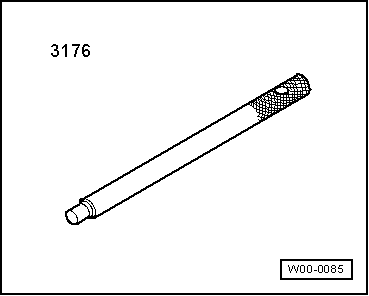

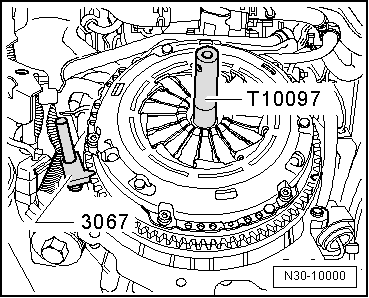

| Clean input shaft splines and, on used clutch plate, hub splines. Remove corrosion and apply only a very thin coat of clutch plate spline grease -G 000 100- to splines. Then move the clutch plate on the input shaft from side to side, until the hub moves smoothly on the shaft. Excess grease must be removed. |

| t

| Pressure plates are protected against corrosion and greased. Only the contact surface may be cleaned, otherwise the service life of the clutch will be considerably reduced. |

| t

| Pressure plate contact surface and clutch plate lining must make full contact with flywheel. Only then insert bolts. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note