Leon Mk2

|

|

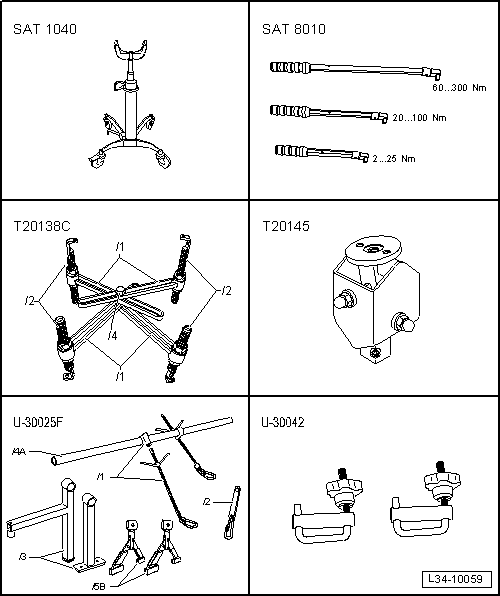

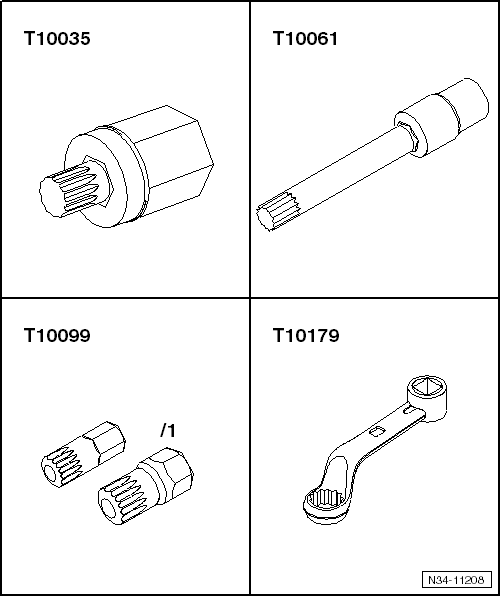

| Special tools and workshop equipment required |

| t | Engine and gearbox jack -SAT 1040- |

| t | Torque wrench kit -SAT 8010- |

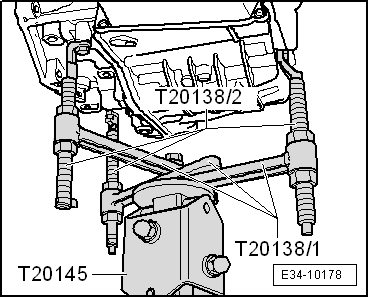

| t | Gearbox support -T20138C- |

| t | Rack -T20145- |

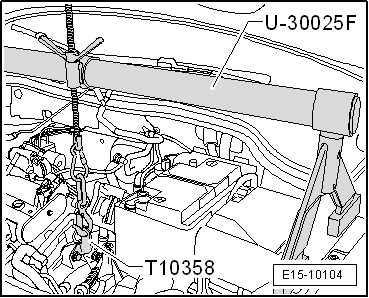

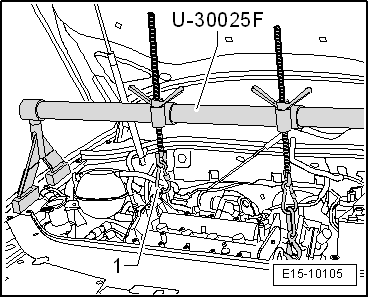

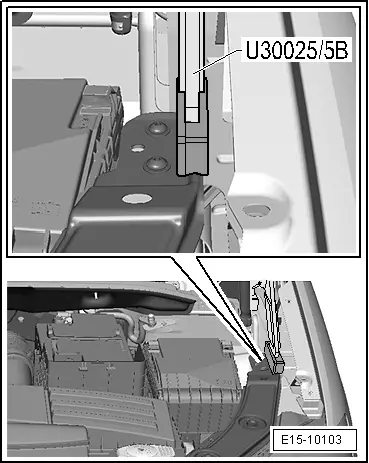

| t | Engine support -U30025F- |

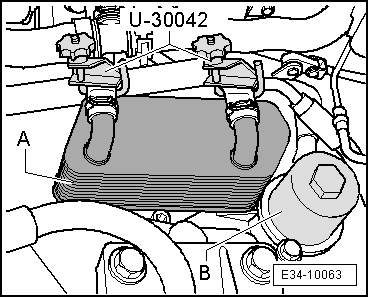

| t | Thrust piece -U30042- |

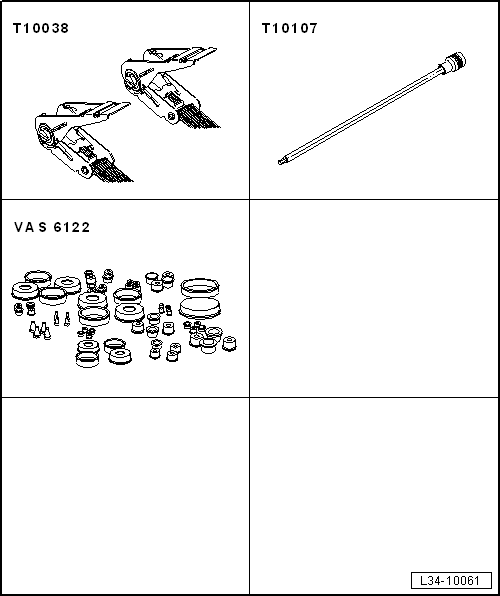

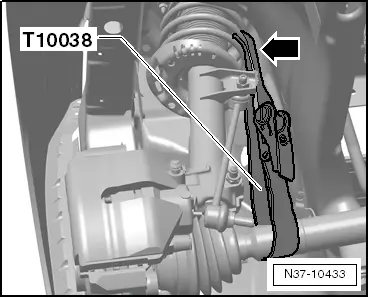

| t | Tensioning tool -T10038- |

| t | Socket and key -T10107A- |

| t | Engine sealing plug set -VAS 6122- |

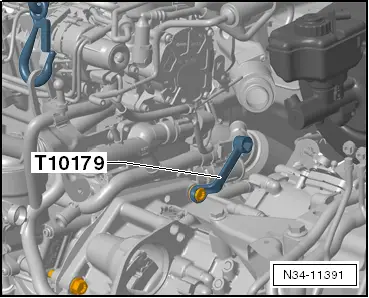

| t | Spanner -T10179- |

| t | Spring retainer -T10358- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

|

|