| –

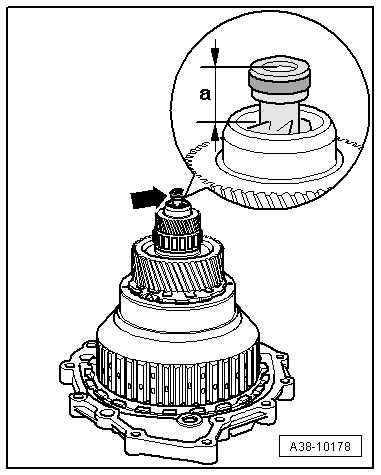

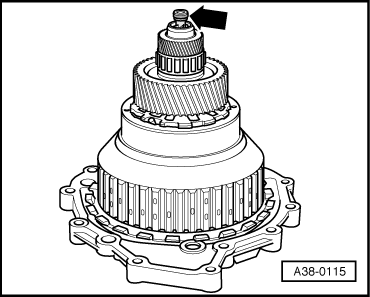

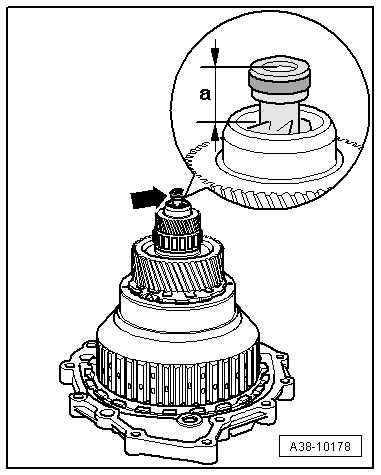

| Check position of oil pipe -arrow- : |

| l

| With oil pipe fully inserted, distance -a- from end of oil pipe to input shaft should be approx. 11.5 mm. |

| If the distance is less, the oil pipe may be damaged (the end could have broken off if the oil pipe was pushed in too far). |

| If the distance is larger, the oil pipe is not pushed in far enough. |

Caution | t

| Do not put down input shaft on the protruding oil pipe -arrow-, as oil pipe would then become damaged. |

| t

| A damaged oil pipe will cause drive-away problems or complete gearbox failure. |

|

| –

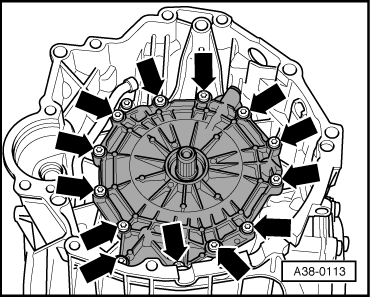

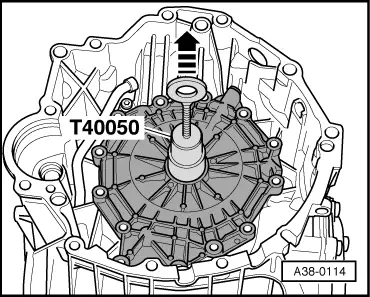

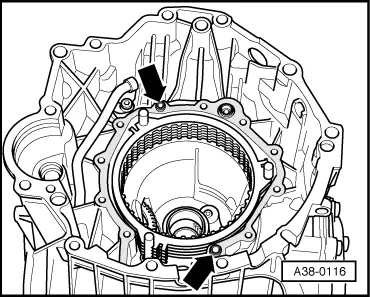

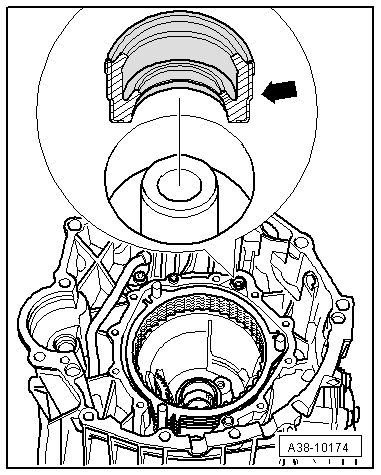

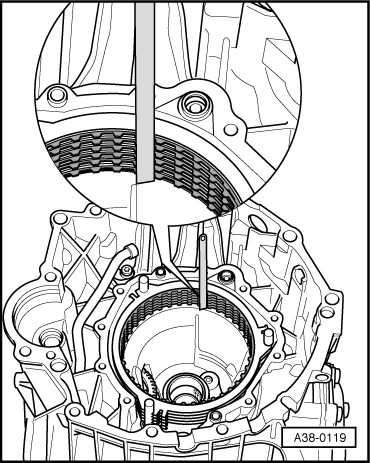

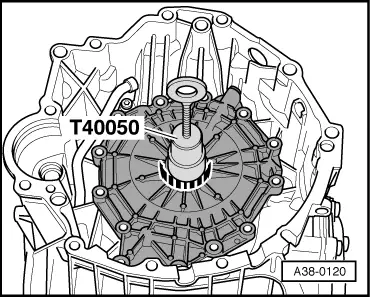

| Insert complete input shaft assembly in gearbox housing. |

|

|

|

Note

Note Note

Note

Note

Note

Caution

Caution