| –

| Clean input shaft splines and lightly grease with -G 000 100-. |

| –

| Move the clutch plate backwards and forwards on the input shaft until it slides freely. Remove excess grease. |

| –

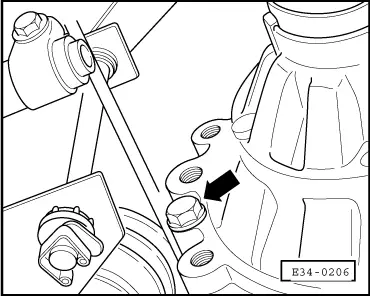

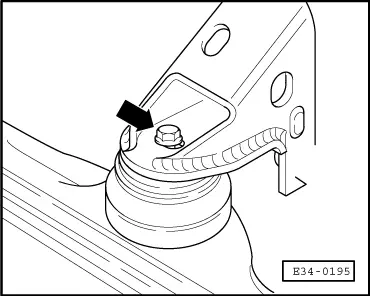

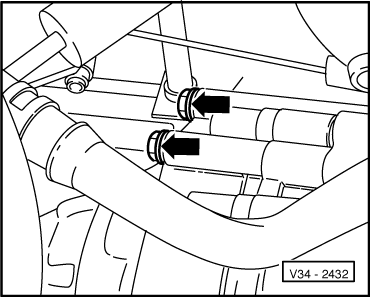

| Check that the gearbox/engine dowel pegs are fitted to the engine, if not, fit them → |

| –

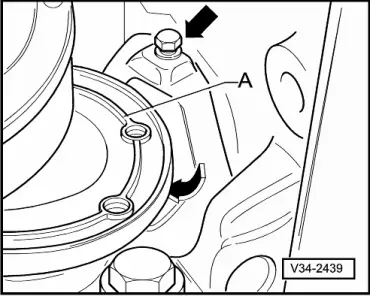

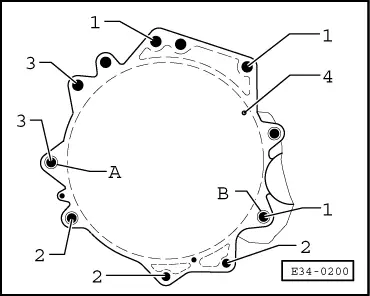

| Make sure the intermediate plate is correctly seated on the engine. |

| –

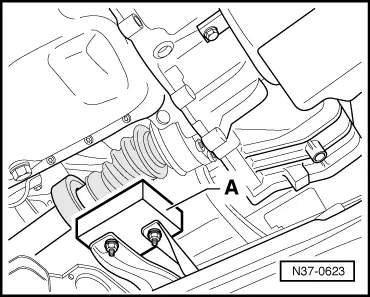

| Place the gearbox on the SAT 1001 A engine/gearbox jack. |

| –

| Push the engine forwards with the assistance of another mechanic. |

| –

| Fit the gearbox to the engine taking care to cause no damage. |

| –

| If necessary, turn the crankshaft until the input shaft teeth mesh with the clutch teeth. |

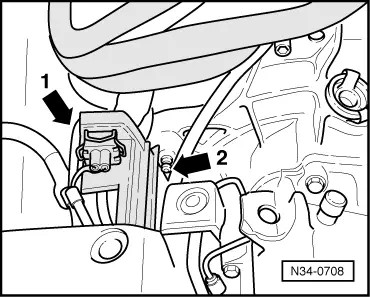

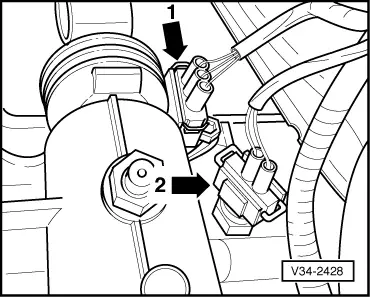

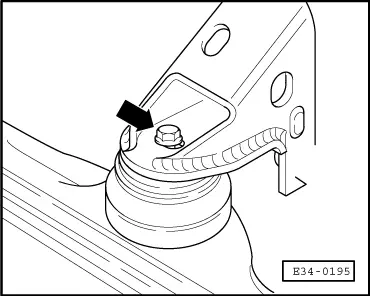

Note! | On fitting the gearbox make sure that the input shaft and the adjustment bushes are correctly located. |

| –

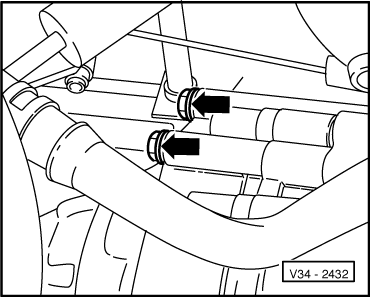

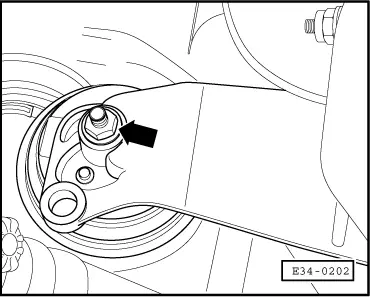

| Fit the lower bolts that secure the engine to the gearbox. |

| –

| Raise the engine, using the left hand spindle of the support tool, until it is level. |

|

|

|

Note!

Note!

Warning

Warning