Leon Mk2

Note

Note

|

| 1 - | Securing ring |

| q | Replace |

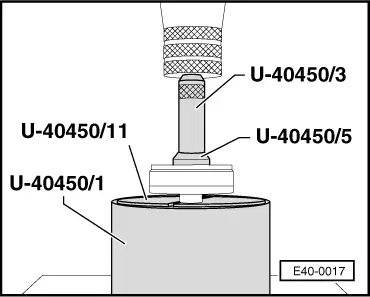

| q | Extract and insert with -A-81124- |

| 2 - | Joint |

| q | To replace, remove the protection layer and attach it to the joint |

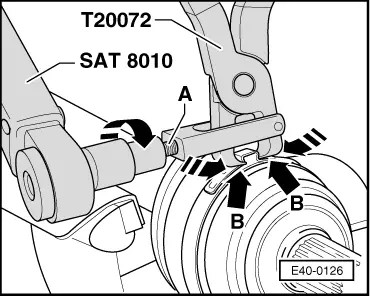

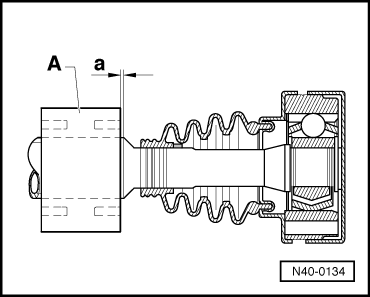

| 3 - | Inner constant velocity joint |

| q | Only replace entirely |

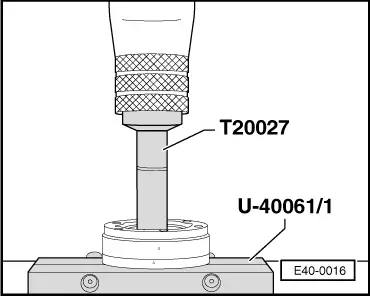

| q | Releasing → Fig. |

| q | Insertion → Fig. |

| q | Grease → Anchor |

| q | Verification → Chapter |

| 4 - | Plate spring |

| q | Cogs on the Ø interior. |

| q | Fitting position: Ø the largest (concave side) rests on the constant velocity joint. |

| 5 - | Right hand side articulated half shaft (tubular shaft) |

| 6 - | Left hand side articulated half shaft (solid shaft) |

| 7 - | Clamp |

| q | Replace |

| q | Tension → Fig. |

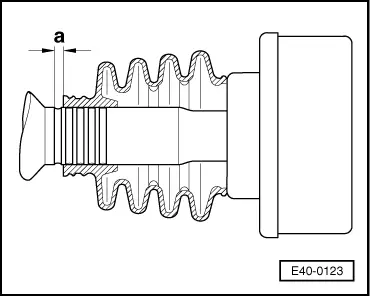

| 8 - | Dust guard |

| q | Ensure that there is no damage or cracks from friction |

| q | Installation position for the left and right wheel drive shafts → Fig. |

| 9 - | Clamp |

| q | Replace |

| q | Tension → Fig. |

| 10 - | Plate spring |

| q | Ø the largest side(concave side): joined to the retaining ring |

| 11 - | Retaining ring |

| 12 - | Securing ring |

| q | Replace |

| q | Fit into the groove on the complete half-shaft |

| 13 - | Constant velocity exterior joint |

| q | Only replace entirely |

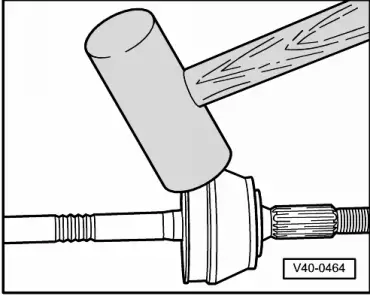

| q | Removing → Fig. |

| q | Fitting: fit onto the complete half-shaft as far as possible by hitting with a plastic hammer |

| q | Grease → Anchor |

| q | Verification → Chapter |

| 14 - | Hexagonal self-locking nut |

| q | Tighten → Anchor |

| q | Before screwing the nut on, clean the remains of paint and/or corrosion that may be on the screw thread of the exterior joint. |

| q | Replace after removing |

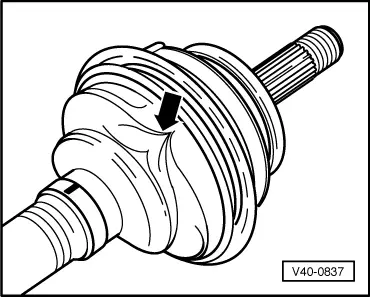

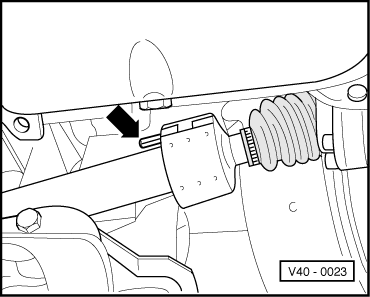

| 15 - | Counterweight |

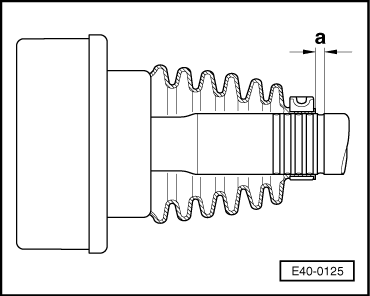

| q | Removing and installing → Fig. |

| q | Installation position → Fig. |

| q | Only on the RHS articulated half shaft |

| q | Diesel engine vehicles |

| 16 - | Bolt with interior multiple cog |

| q | 45 Nm |

| 17 - | Supplement |

| 18 - | Clamp |

| q | Replace |

| q | Tension → Fig. |

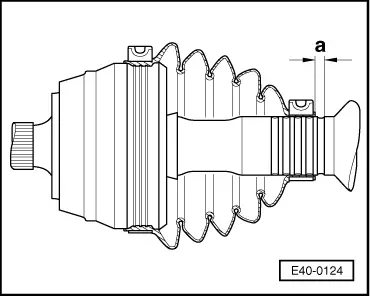

| 19 - | Dustguard for interior constant velocity joint |

| q | Ensure that there is no damage or cracks from friction |

| q | Installation position for the left and right wheel drive shafts → Fig. |

| q | Installation position for the right wheel drive shaft → Fig. |

| q | Take out using a punch. |

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|